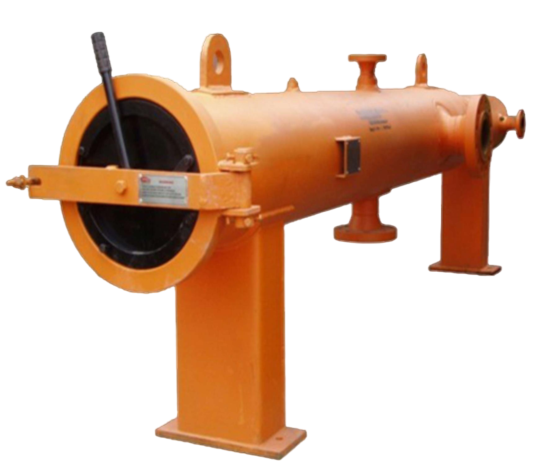

ABOUT EQUIPMENT

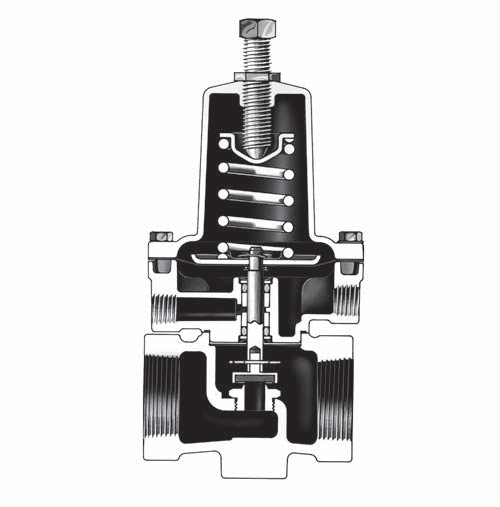

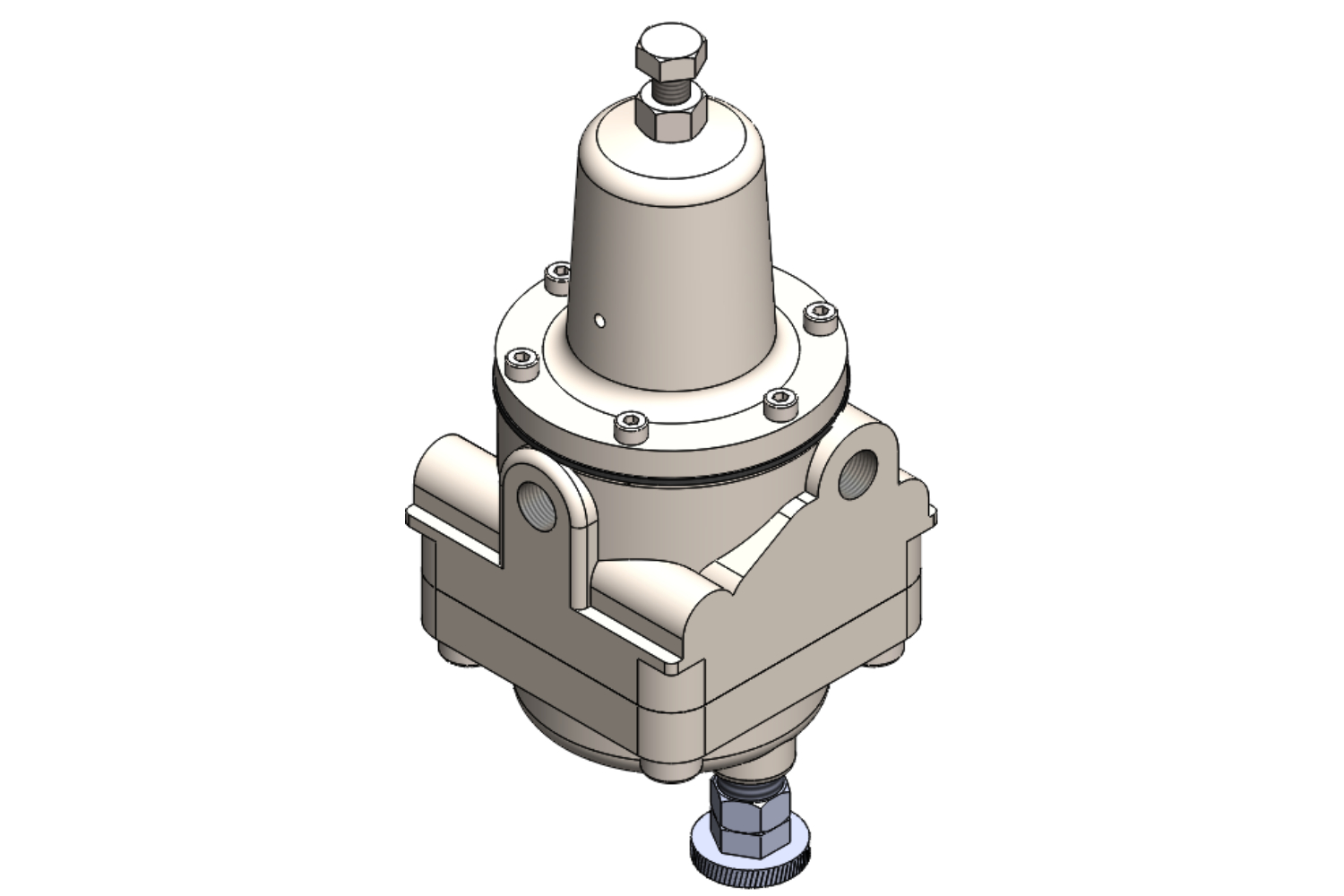

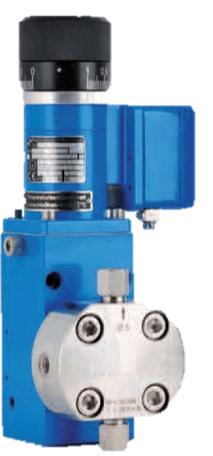

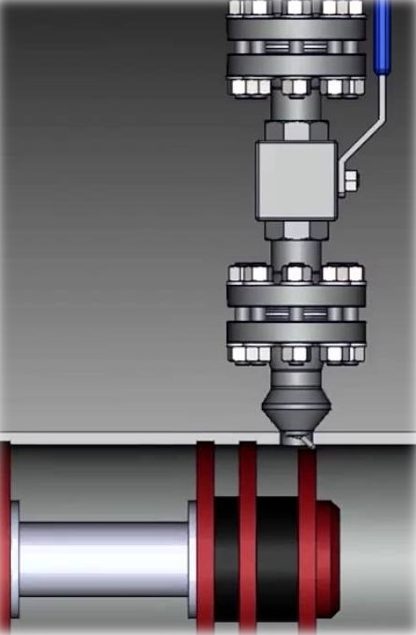

CONTROL VALVE 119

Features

- Easy Installation;

Compact, light weight construction permits easy handling and installation.

- Easy Leak Detection;

Vent hole between body and actuator stem seals allows detection of body or actuator seal leakage.

- Easily Adjusted Spring;

The 119 Series spring is adjusted by rotating the adjusting screw on the top of the spring case.

- Easy Maintenance;

The fuel gas valve can be completely disassembled without removing the valve body from the line.

- Low Leakage;

The composition disk assembly provides positive shutoff, minimizing seat leakage when downstream demand is zero.

- Sour Gas Service Capability;

Optional materials are available for applications handling sour gases.

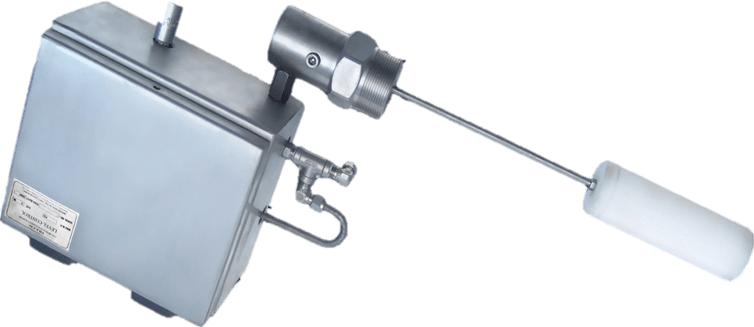

Construction Materials

Valve Body: Cast iron

Spring Case: Aluminum

Bonnet: Aluminum

Disk Holder Assembly: Aluminum and nitrile (NBR) Stainless steel and Fluorocarbon (FKM)

Orifice: Aluminum

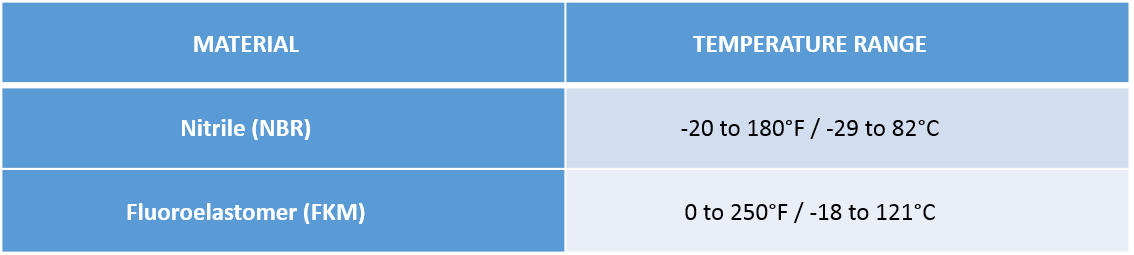

Diaphragm: Nitrile (NBR) or Fluoroelastomer (FKM)

O-Rings: Nitrile (NBR) or Fluoroelastomer (FKM)

Adjusting Screw:Steel

Spring: Steel

Material Temperature Capabilities

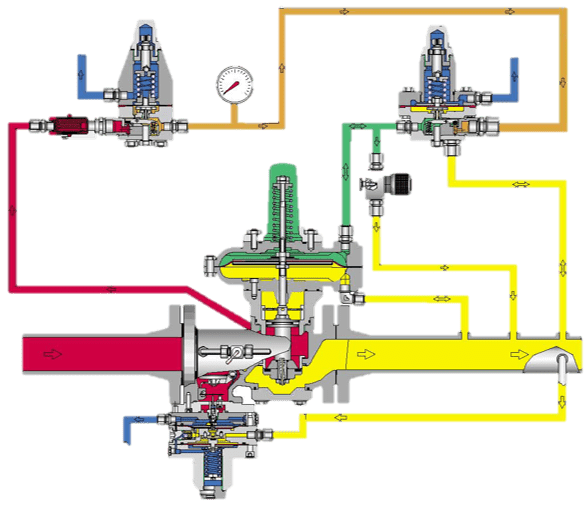

Principle Of Operation

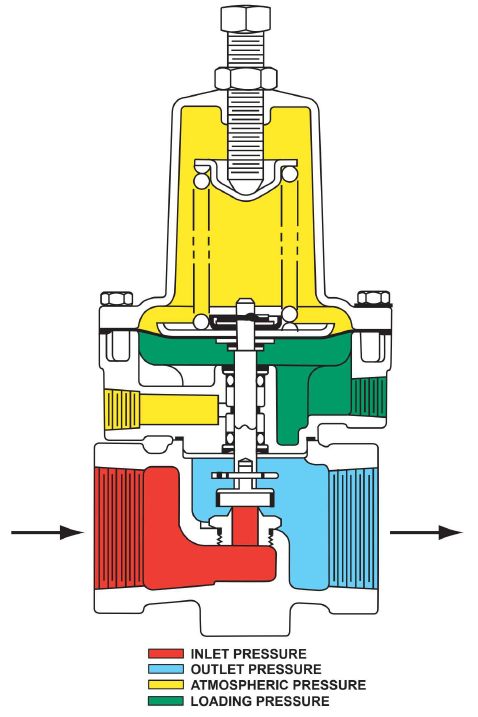

As loading pressure is applied to the 119 Series fuel gas valve diaphragm, the disk holder moves away from the orifice. As loading pressure is reduced, the opposing spring force moves the disk holder toward the closed position, resulting in spring-close action should a loss of loading supply pressure occur.

Technical Data

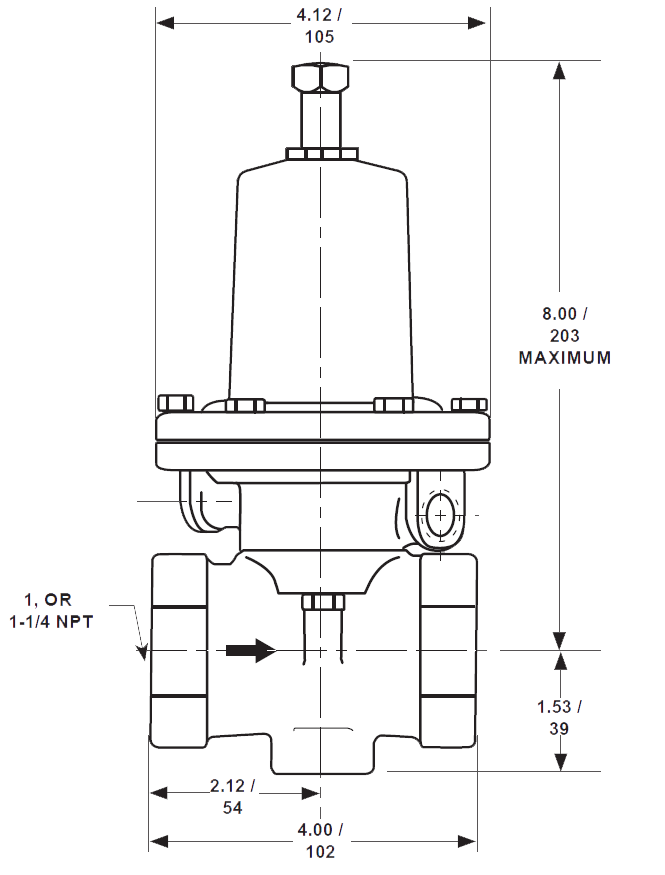

Body Sizes and End Connection Styles

Body Sizes and End Connection Styles 1, or 1-1/4-inch NPT screwed

Maximum Inlet Pressure150 psig (10.34 bar)

Pressure Setting AdjustmentMay be adjusted throughout each spring range by rotating the adjusting screw

Valve Plug Travel3/16-inch (5 mm)

Actuator Pressure Connection1/4-inch NPT female

Spring Case and Bonnet Vents1/4-inch NPT female

Contact Us

Contact Us Engineering Group

Engineering Group

Creative Strategy

Creative Strategy Download

Download