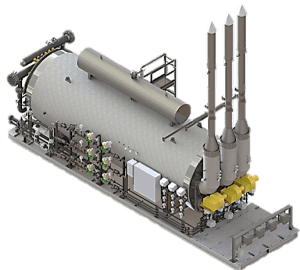

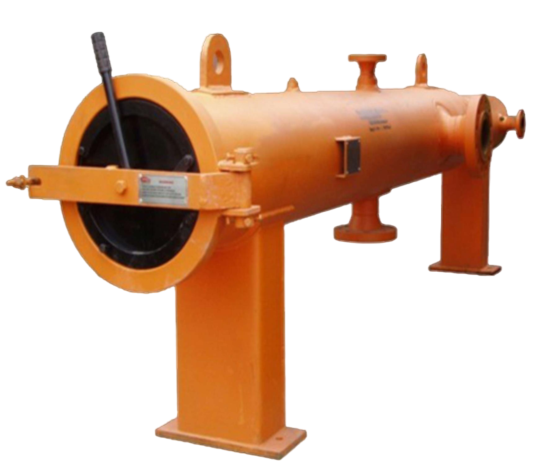

ABOUT EQUIPMENT

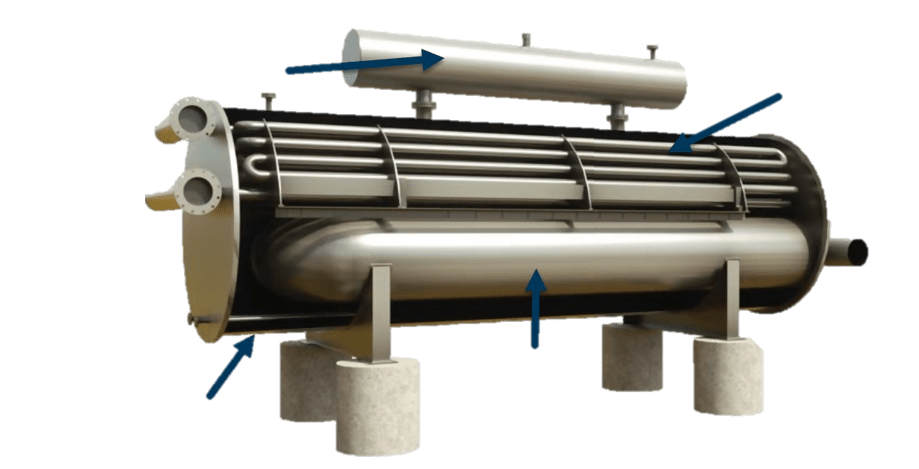

DYNAMIC MIXER

EQUIPMENT

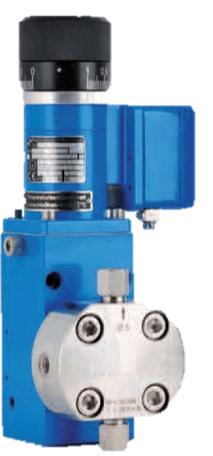

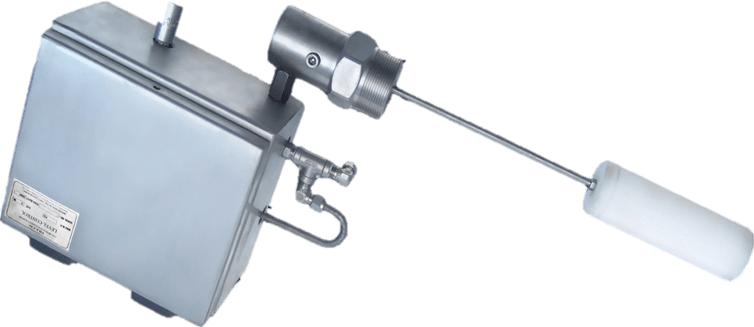

Dynamic mixers or propeller stirrers are used to mix chemicals (liquid-liquid/liquid-solid/ liquid-gas, homogenization of solutions, heat transfer, etc).

The dynamic rotational movement introduces radial and thrust forces into the fluid layers and this creates flow. With the rotation of the blade of the device, the fluid flow in the tank is formed, which is turbulent and causes mixing. By angling the blades, the fluid can be directed down or up in addition to the surroundings.

Application

-

Increasing the speed of composition.

-

Mixing two non-homogeneous substances.

-

Coagulation.

-

Laboratory use.

-

Dilution.

-

Phase change of a chemical substance such as solid to liquid.

-

Reaching the desired stage such as the polymerization process.

-

The heat transfer.

Benefits

Homogenization in the shortest possible time.

The possibility of adjusting the intensity of mixing and stirring speed.

Ideal for use in various industries.

Material

Shaft: Steel, Aluminium, …

Blades: Stainless Steel, Epoxy Coated Steel, Plastic Coated Steel, …

Types of Blades

Pitched Blade.

Pitched Blade.

Hydrofoil Type

Hydrofoil Type

Marine Propeller

Marine Propeller

Disk Turbine (Rushton)

Disk Turbine (Rushton)

Helical Ribbon

Helical Ribbon

Anchor Impeller

Anchor Impeller

* Viscosity determines the size of the blades and the rotation speed.

Contact Us

Contact Us Engineering Group

Engineering Group

Creative Strategy

Creative Strategy Download

Download