ABOUT EQUIPMENT

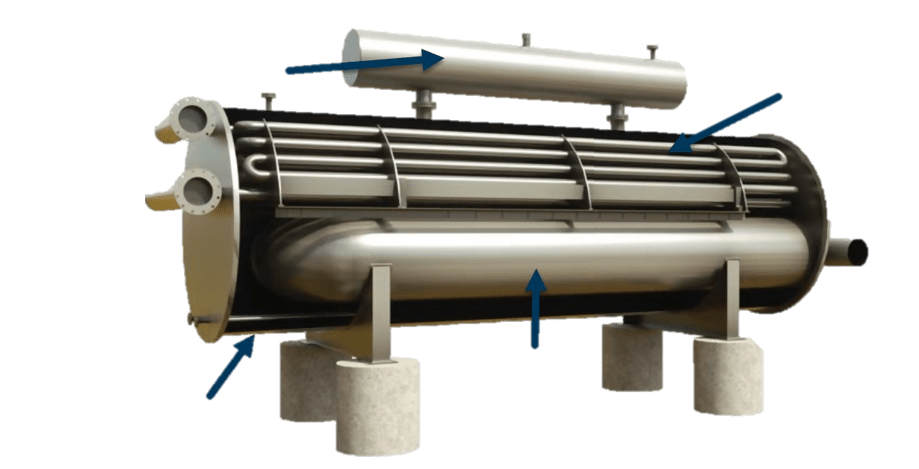

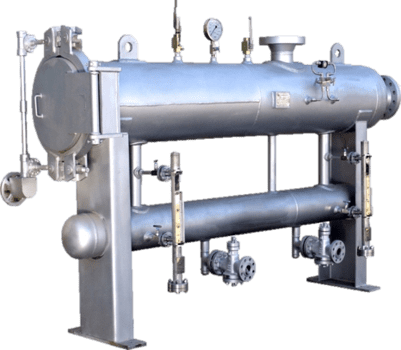

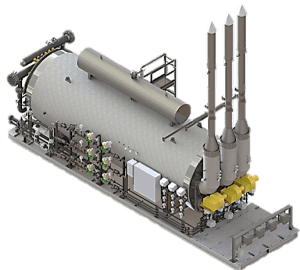

INDIRECT ATMOSPHERIC WATER BATH HEATER

When regulating of pressure events the gas temperature will cool approximately 7º F per 100 psig drop in pressure (or 1º F per 15 psig drop in pressure). So we must prepare, adequate heating facilities to prevent regulator freezing. It means that we must use a heat exchanger device are named Water Bath Heater.

ABOUT EQUIPMENT

APPLICATION

When regulating of pressure events the gas temperature will cool approximately 7º F per 100 psig drop in pressure (or 1º F per 15 psig drop in pressure). So we must prepare, adequate heating facilities to prevent regulator freezing. It means that we must use a heat exchanger device are named Water Bath Heater.

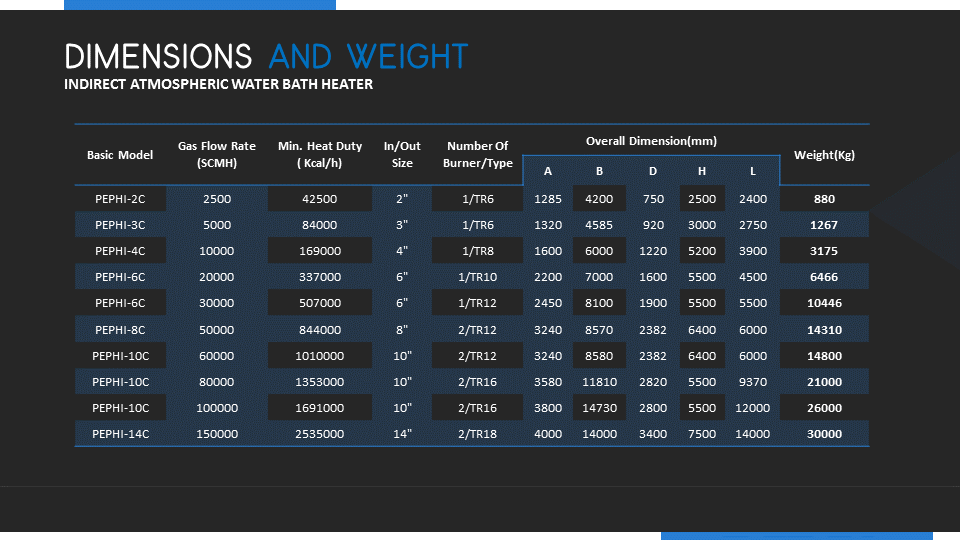

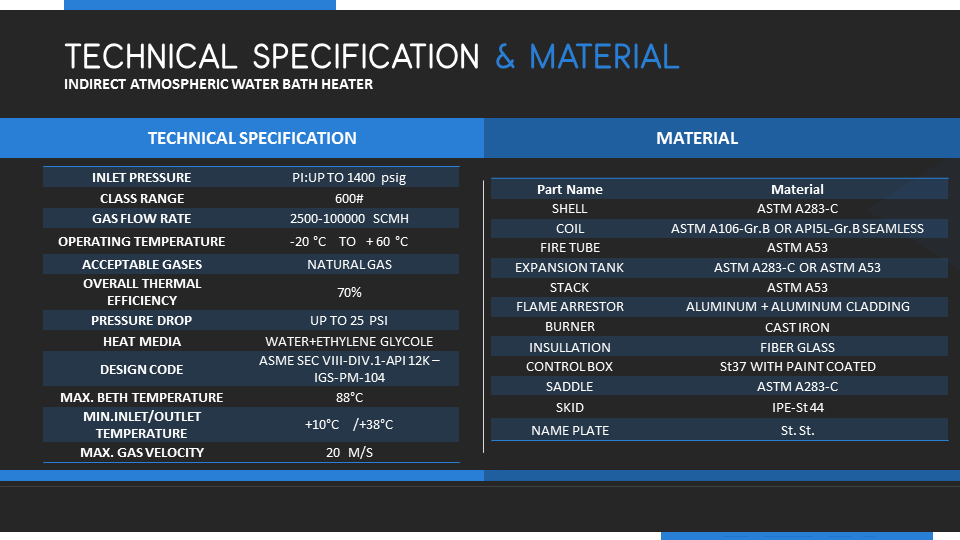

PEPCO delivery program includes Indirect Water Bath Heaters for many different applications and duties using Water and Water-Glycol as heat transfer media. PEPCO Bath Heaters are specifically designed to meet the precise requirements of any process application and customer or regulatory specifications such as API 12K and/or other national/international codes.

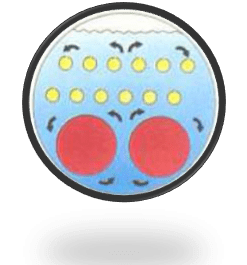

PRINCIPLES OF OPERATION

Why should you trust our WHCP?

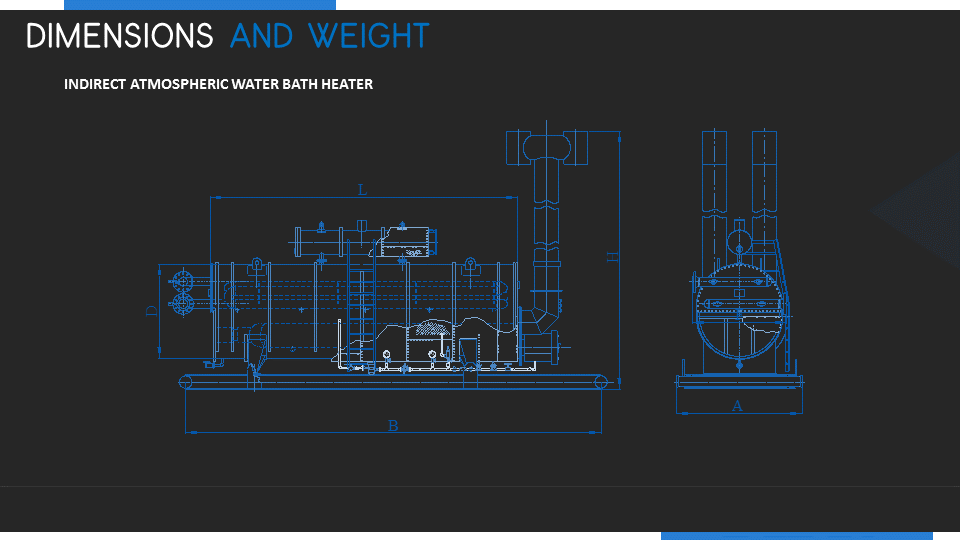

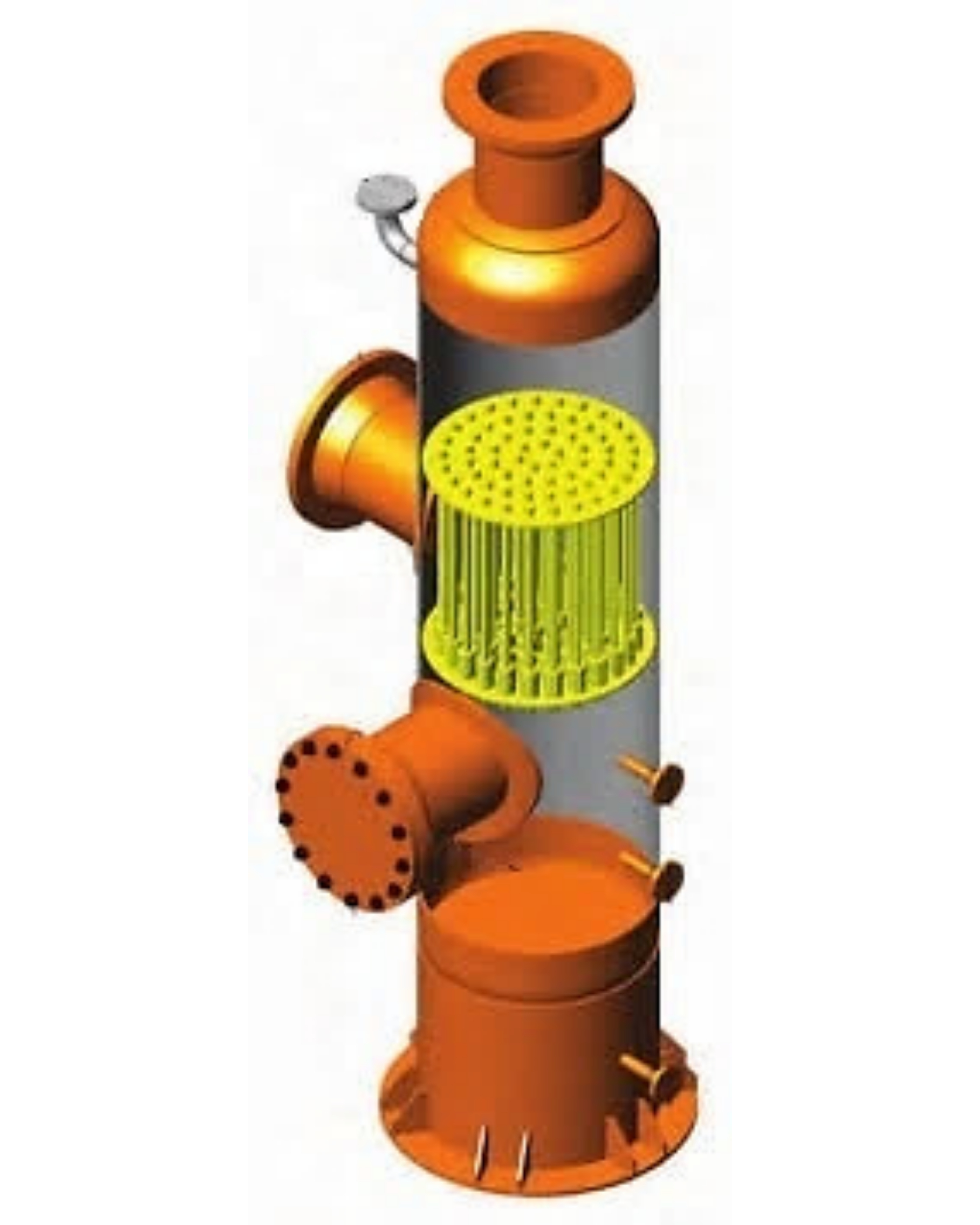

- Fire Tube

- Shell

- Process/Flow Coil.

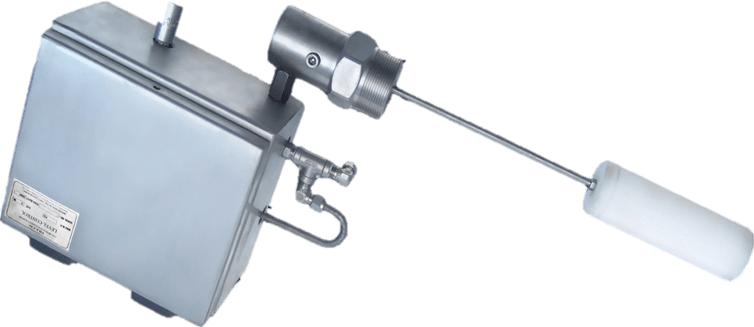

The “U” Shaped fire tube is located in the lower half of the shell fully immersed in the water bath. Fuel gas is burned within the fire tube releasing heat through the wall of the fire tube to the water bath maintaining temperature up to 1900F (880C). The heated water bath then transfers heat through the tube wall to the fluid flowing through the process/flow coil or a series of tubes which are located in the upper half of the vessel. Typical fluids to be heated are well streams, oil, natural gas etc. The fire tube gas supply is controlled by a temperature controller in order to maintain the required bath temperature for the actual inlet and/or outlet conditions.

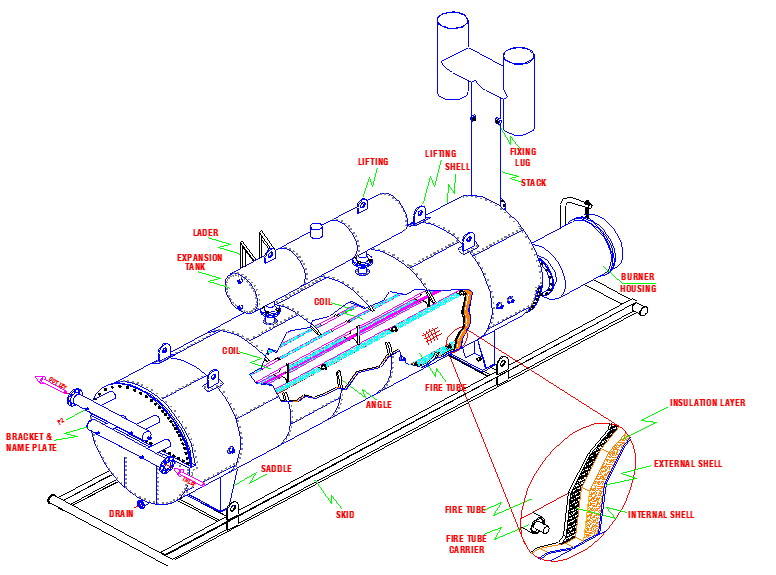

HEATER COMPONENTS

- Shell

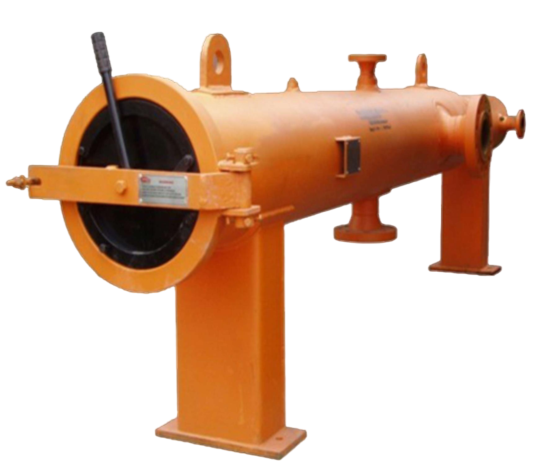

- Fire Tube

- Process Coil

- Fuel Line & Instruments

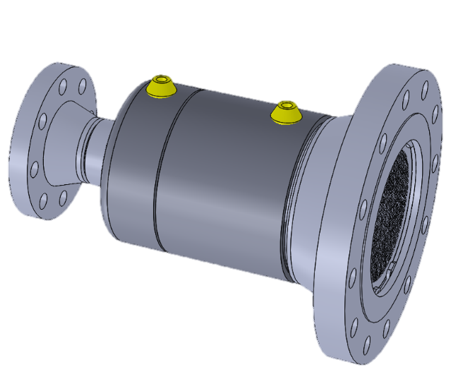

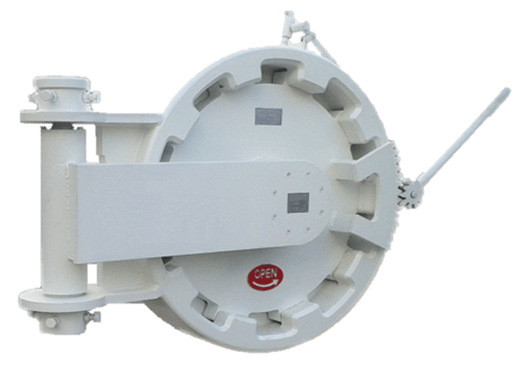

- Flame Arrestor

- Skid & Ladder

- Expansion Tank

- Insulation

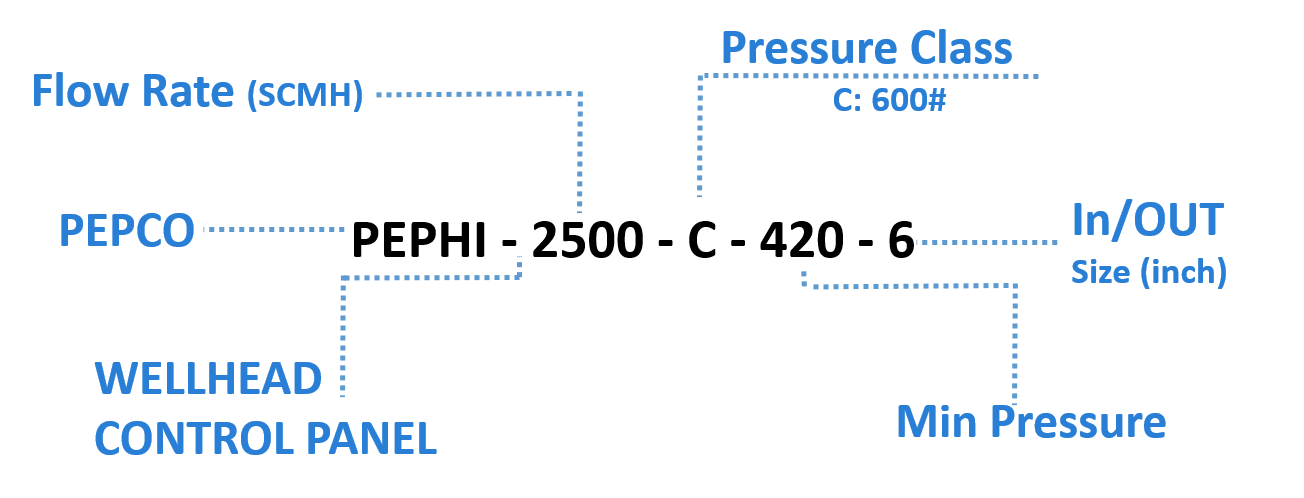

TYPE DESIGNATION

FEATURES

DESIGN AND CONSTRUCTION ADVANTAGES

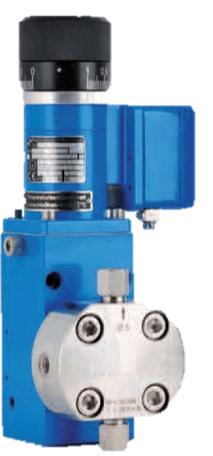

Standard Features

- Removable fire tube

- Natural draft burner

- Thermostat

- High efficiency burner system

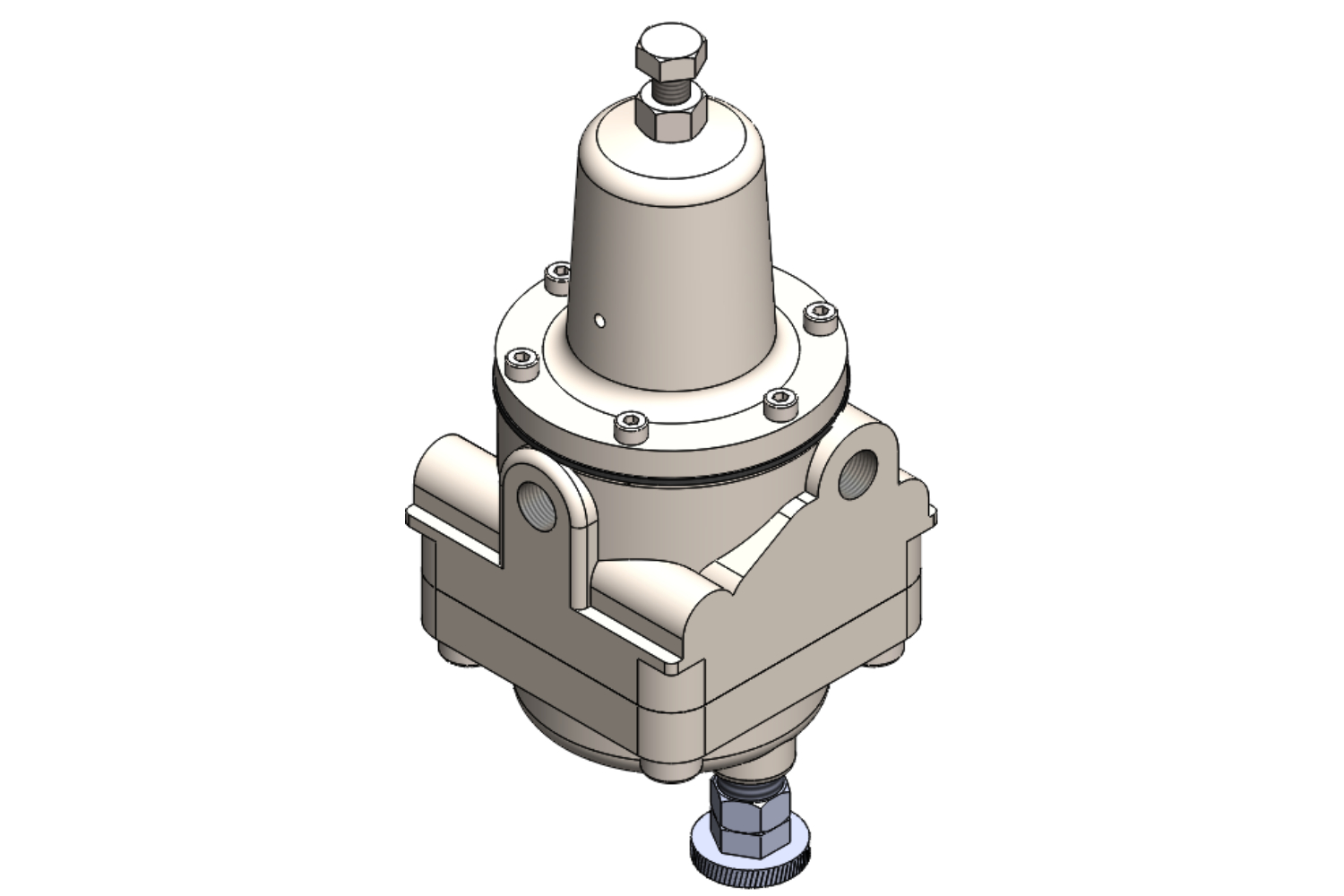

- Flame arrestors

- Pilot guard safety shut down

- Fuel shut down valve

- Insulation

- Primer (1 Coat) + Enamel Paint (2 Coats)

- Removable flow coil

- Fuel gas preheat coil

- Fuel gas system c/w piping, filter, valves & Instruments

- Fire tube stack

Optional Features

- Thermostat

- High efficiency burner system

- Flame arrestors

- Pilot guard safety shut down

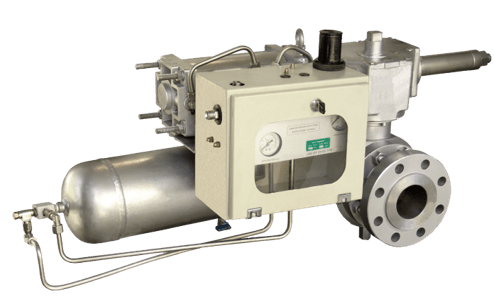

Applications

- Heating high pressure gas and/or oil in oilfield production

- main gas distribution stations prior to pressure reduction to prevent hydrate formation

- Heating highly viscous oils to reduce pumping pressures and to boost efficiency

- Heat oil producing well streams

HEAT MEDIA

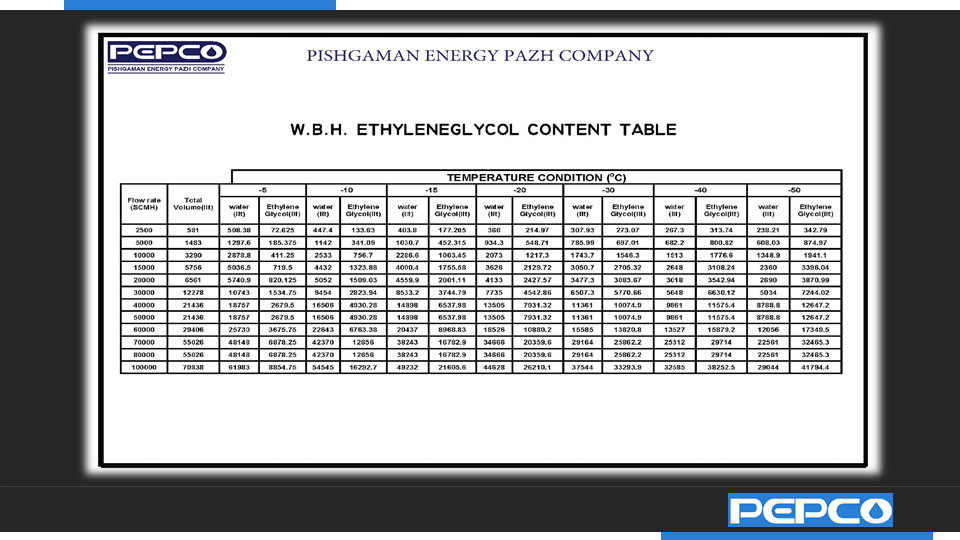

Freezing of water bath is a potential problem. If the heater is insulated, a continuous pilot suffices. Glycols are generally accepted as the safest and most trouble-free additives. THECO Glycol content table available on page 8 for several ambient temperatures.

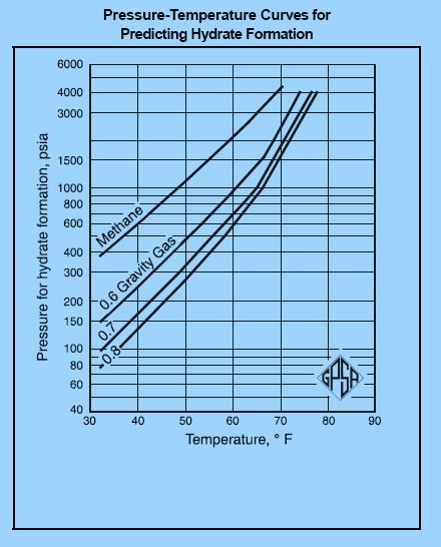

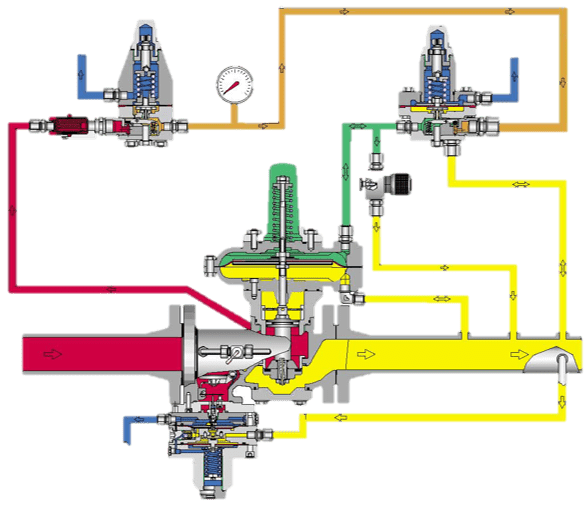

HYDRATE FORMATION

Whenever natural gas is decompressed, its temperature goes down. This temperature change is called the “joule-Thompson effect”. Figure below used for first approximations of hydrate formation conditions and for estimating permissible expansion of natural gas without the formation of hydrates.

Contact Us

Contact Us Engineering Group

Engineering Group

Creative Strategy

Creative Strategy Download

Download