ABOUT EQUIPMENT

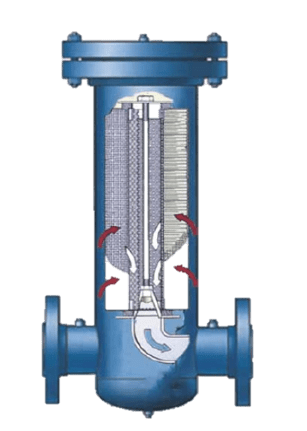

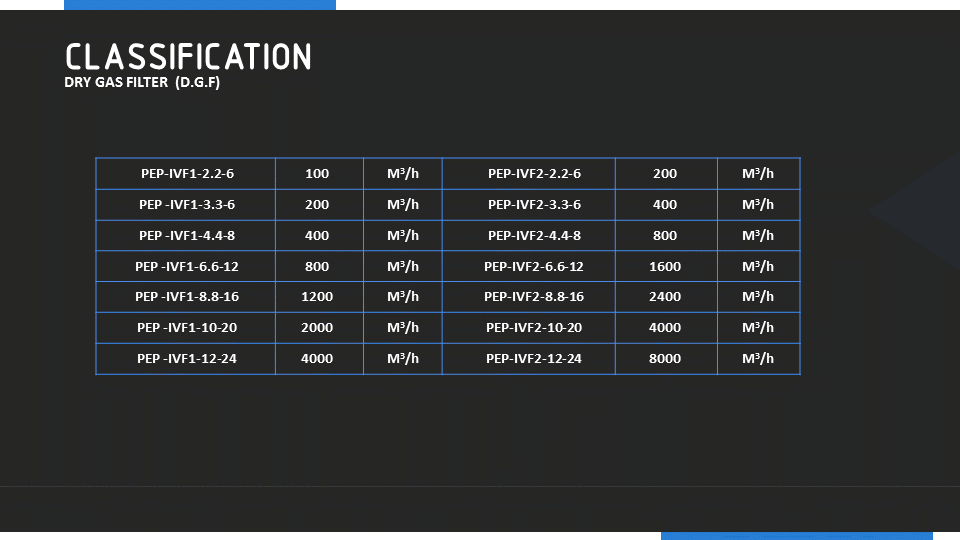

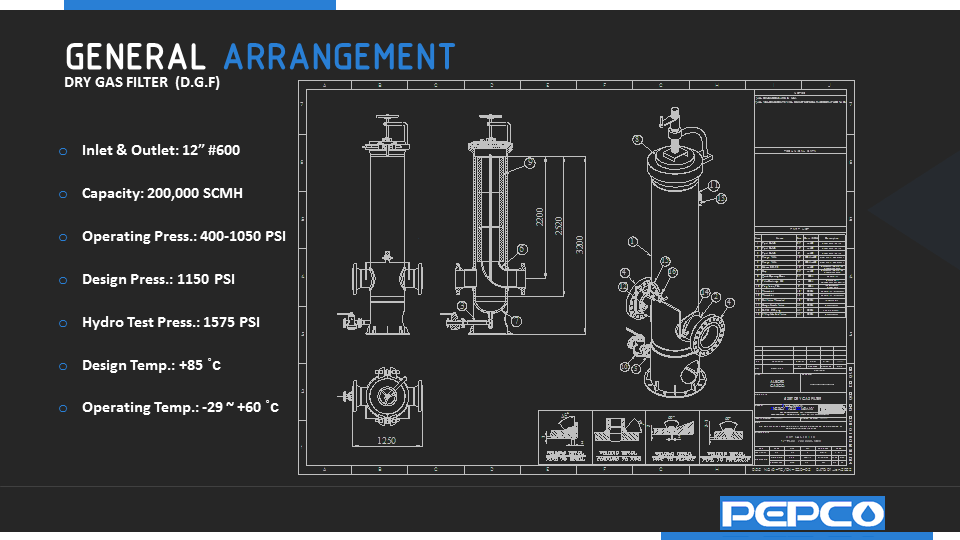

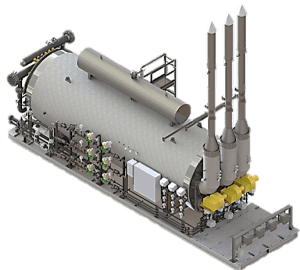

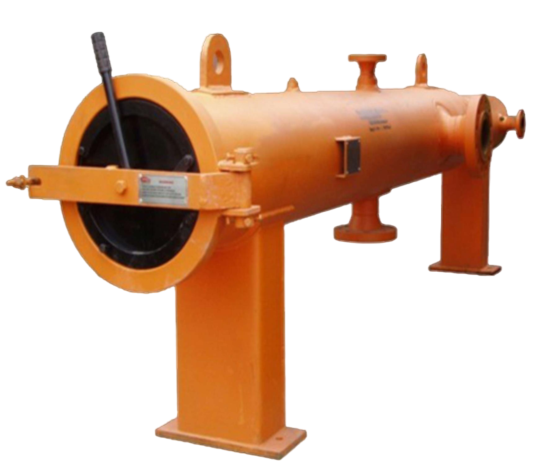

DRY GAS FILTER (D.G.F)

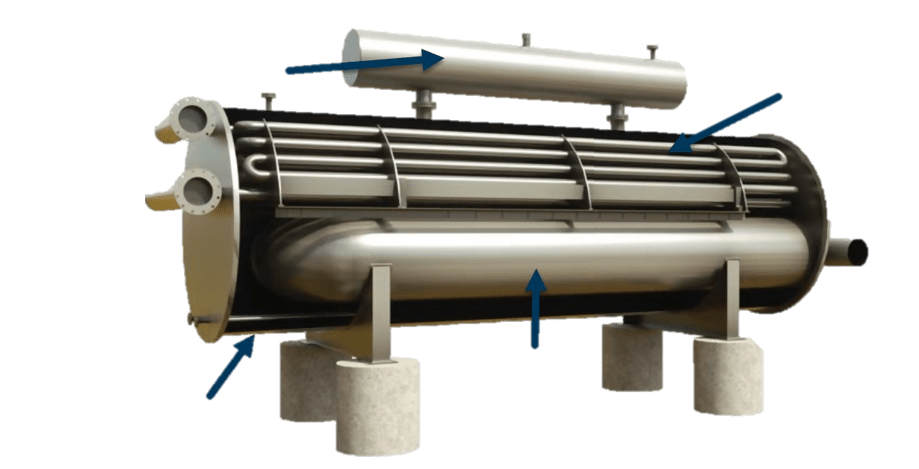

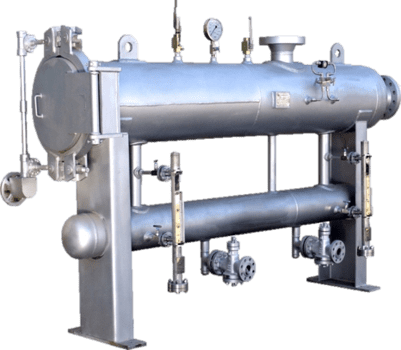

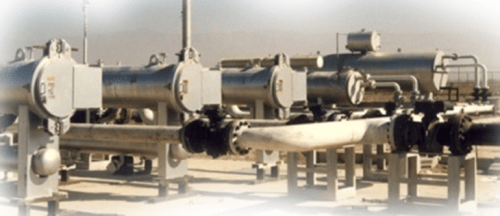

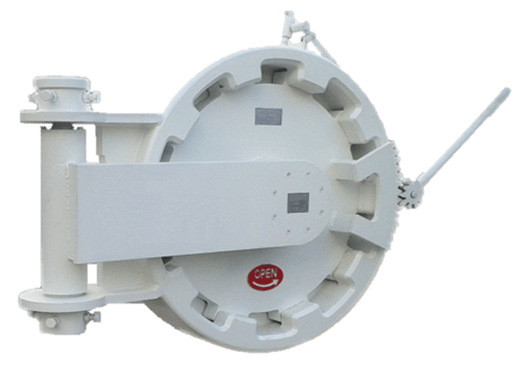

PEPCO dry gas filters are designed to handle a variety of solid and semisolid particle removal applications. Standard design includes Quick Opening Closure and z-bar 4 point element supports. Dry gas filters add the flexibility of using depth fiberglass, depth polyester surface, and rolled fiberglass filter elements to yield optimum economics and maximum performance under almost any service condition. Design is available in all major codes and certifications. Sizes range from 6″ through 120″ diameter in vertical and horizontal configurations.

ABOUT EQUIPMENT

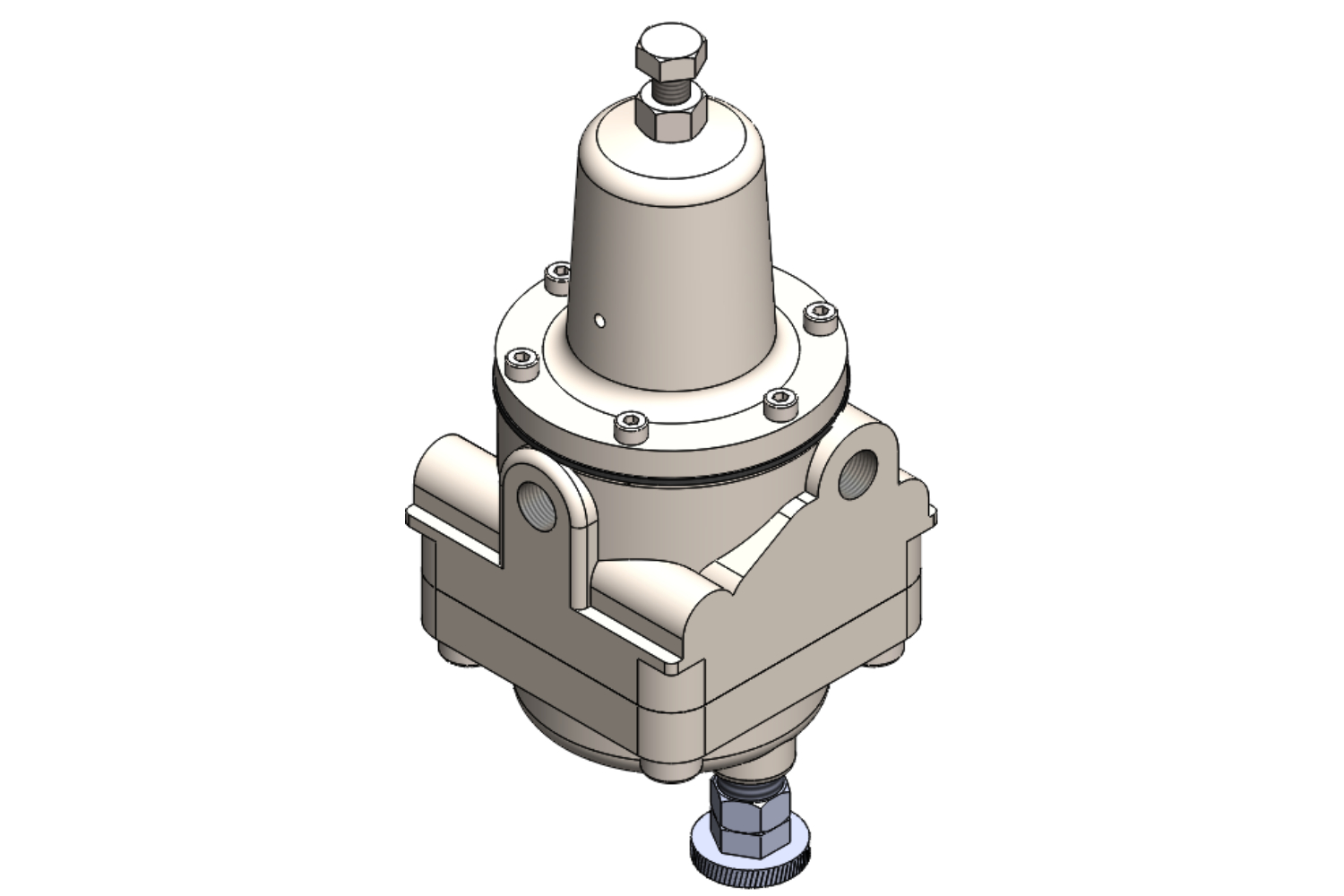

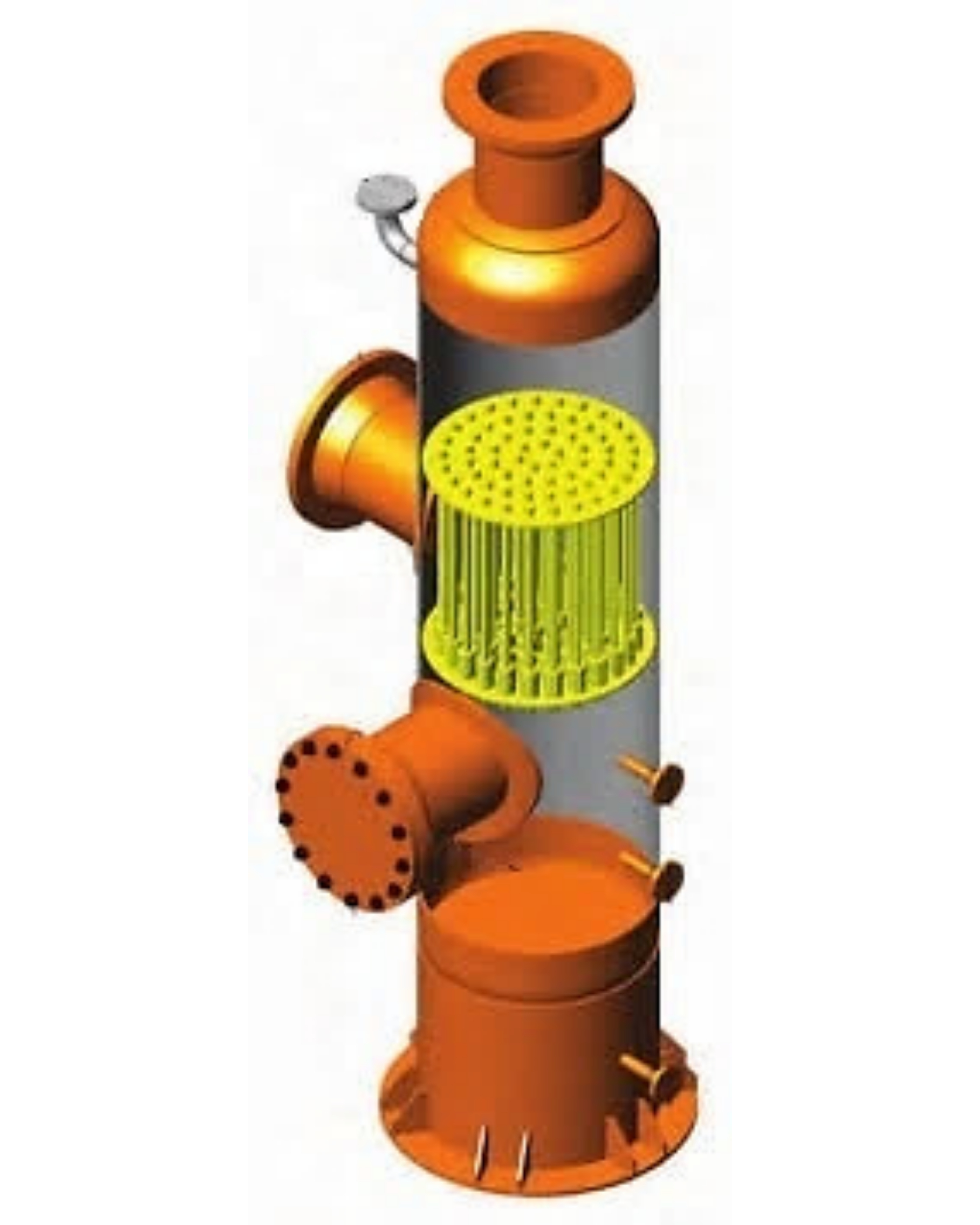

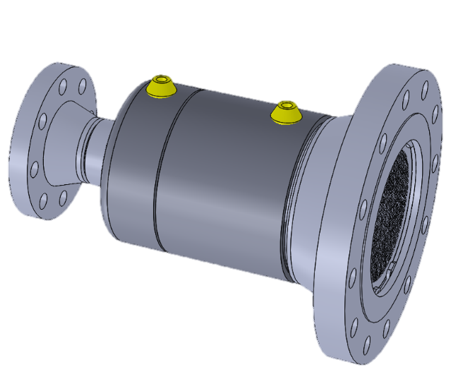

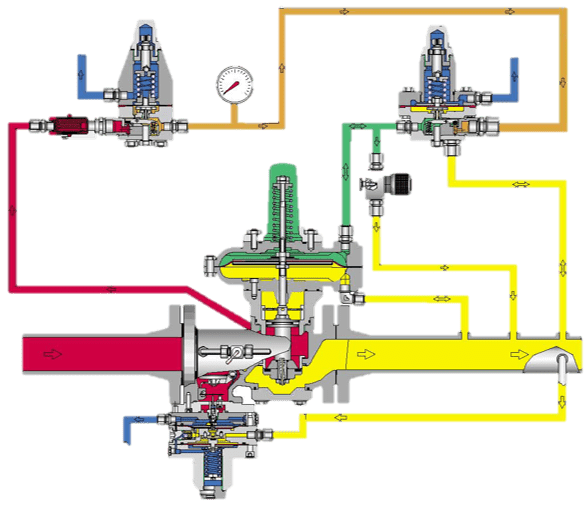

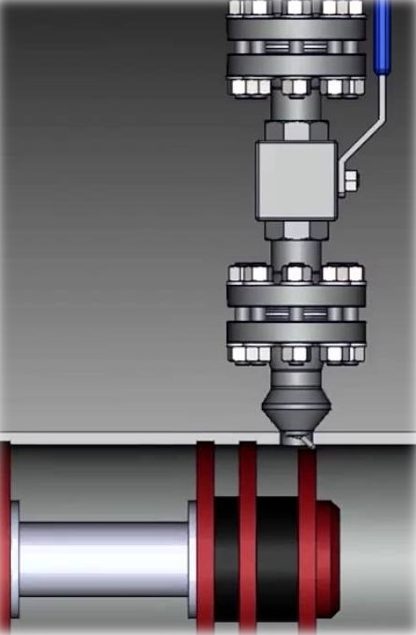

PISHGAMAN ENERGY PAZH CO (PEPCO) PEPCO dry gas filters are designed to handle a variety of solid and semisolid particle removal applications. Standard design includes Quick Opening Closure and z-bar 4 point element supports. Dry gas filters add the flexibility of using depth fiberglass, depth polyester surface, and rolled fiberglass filter elements to yield optimum economics and maximum performance under almost any service condition. Design is available in all major codes and certifications. Sizes range from 6″ through 120″ diameter in vertical and horizontal configurations. For dry gas systems in need of cleaning, the PEPCO GAS DRY FILTER provides efficient removal of solid particulates down to 1 micron in size. The conventional forward-flow Dry Filter employs fiberglass filter elements, which are manufactured by PEPCO Company. These units can be configured horizontally or vertically. An optional feature on the dry filter units is a self-cleaning manifold, which allows a back-flow stream to clean the filter elements while allowing the unit to continue operation in full service. All PEPCO equipment is designed and fabricated by PEPCO Company alone, allowing us to guarantee timely and dependable service to our customers. Horizontal or Vertical Dry Gas Filters, are multistage devices that remove dust and other solids from gas and air, where no liquids are expected. The basic design employs an inlet chamber containing a liquid/solid disengagement area and cylindrical cartridge filter elements. Gas entering the first chamber passes across the standpipes supporting the filters, avoiding direct impingement on the filter elements. Gas laden with solids enters the filter elements, where the solids are trapped.

PRODUCT APPLICATION

The dry gas filters have a fairly high efficiency: in fact, it is possible to reach an efficiency of separation of solid particles having dimensions up to three microns with a percentage of 99.95 percent

- Gas pipelines

- Gas field treatments

- Chemical processing facilities

- Metering and regulating stations

- Gas processing plants

- Petrochemical plants

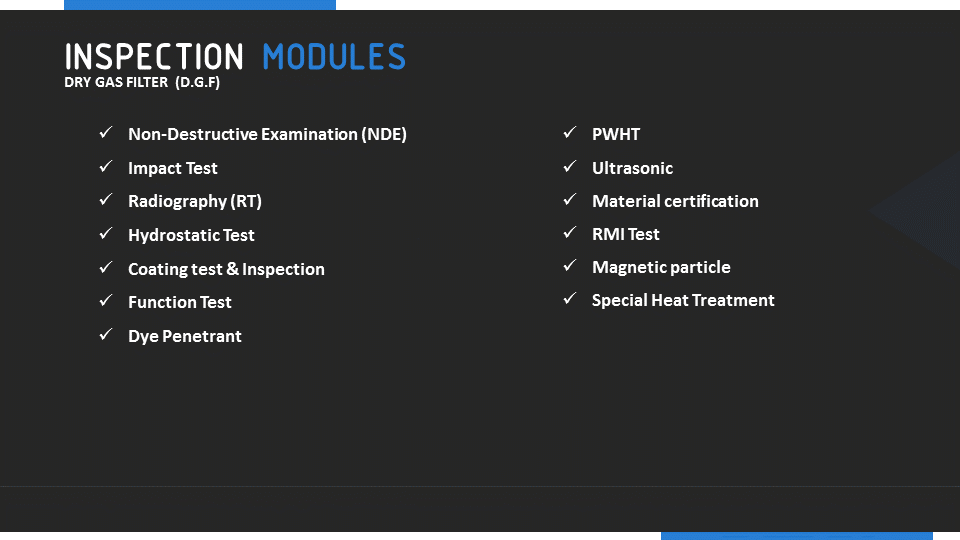

STANDARDS APPLICATION

To guarantee the quality of your selected dry gas filter, verify if it conforms to the following codes and standards:

- ASME Sec VIII, DIV 1

- ISO 8573

- EN 10204 type 3.1

- ASME BPVC

- API 14C (for offshore applications)

- ASME B16.5 and ASME B16.47

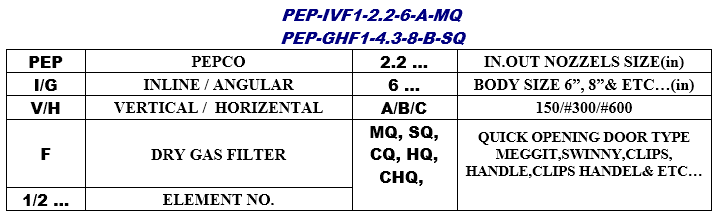

MODEL NUMBER

Contact Us

Contact Us Engineering Group

Engineering Group

Creative Strategy

Creative Strategy Download

Download