ABOUT EQUIPMENT

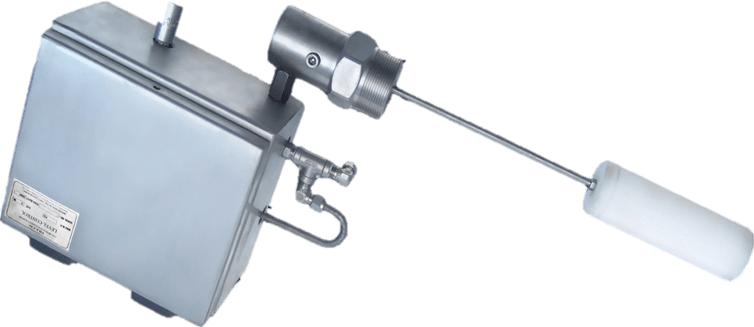

FLOAT OPERATED LEVEL CONTROLLER

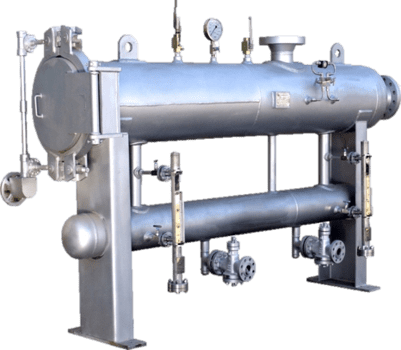

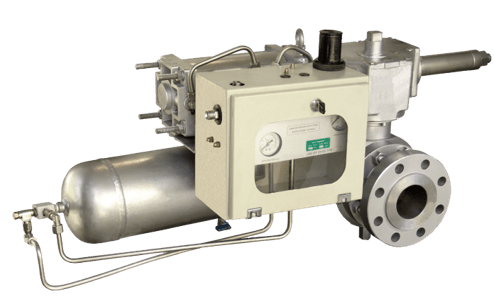

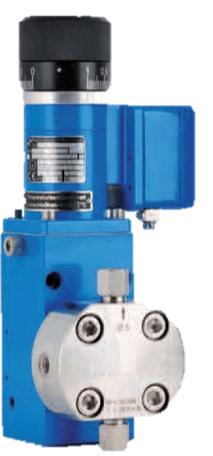

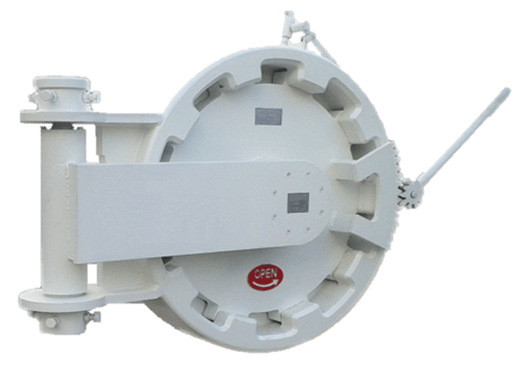

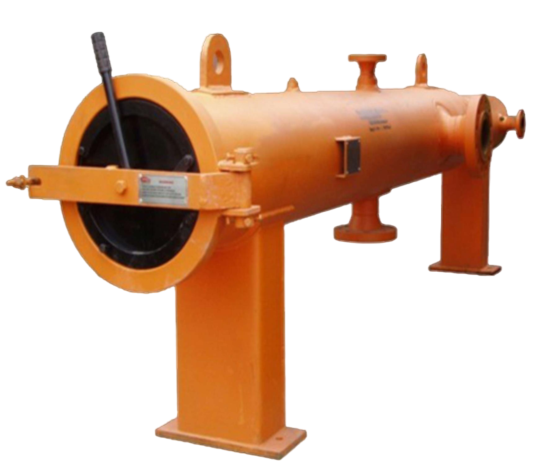

The PEPCO Level Controller is designed for use in liquid level control applications. It provides a snap (on/off) pneumatic output and operates in a direct mode. The LC-2 level controller is equipped with a displacer for horizontal installation. Instrument gas inlet, and pilot outlet are 1/4″ NPT.

ABOUT EQUIPMENT

The PEPCO Level Controller is designed for use in liquid level control applications. It provides a snap (on/off) pneumatic output and operates in a direct mode. The LC-2 level controller is equipped with a displacer for horizontal installation. Instrument gas inlet, and pilot outlet are 1/4″ NPT.

Features

- Simple installation

- Easy to use

- Polyethylene displacement float 0.65 Specific Gravity or higher

- No adjustment required.

OPERATION

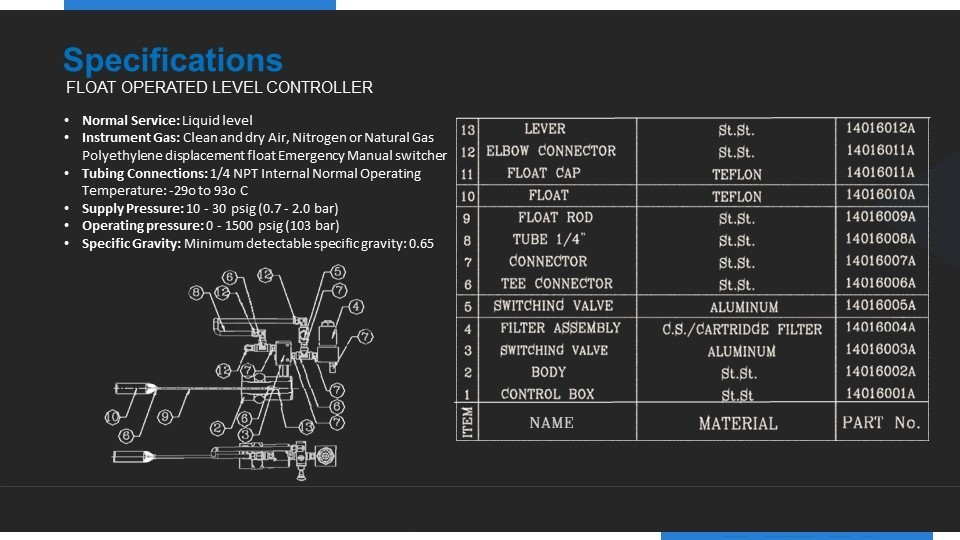

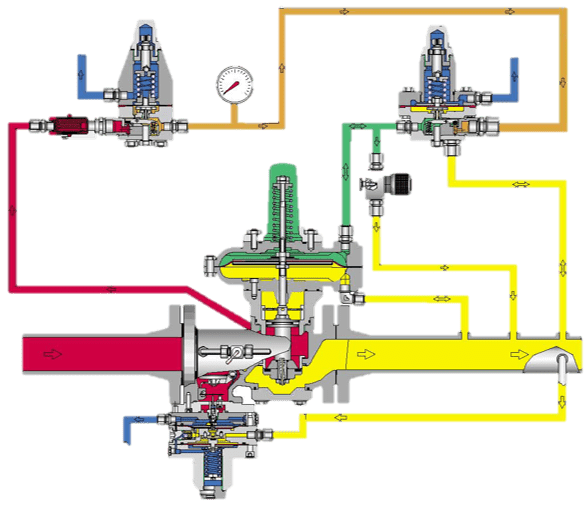

The level control LC-2 consists of a displacement float for monitoring the liquid level, a shaft to transmit float movement, a pilot case which contains a pilot cabinet, switching valves, and actuator assembly. As the liquid level rises, the displaced volume of liquid lifts the displacer. The switching valve turns to open the connection between instrument supply and output to the actuator of the liquid dump valve. As the liquid level lowers, the weight of the displacer forces the arm to close the connection between instrument supply and output.

Installation

Before Installation:

Be sure you fully understand the application, operation and connection of the device before installing.

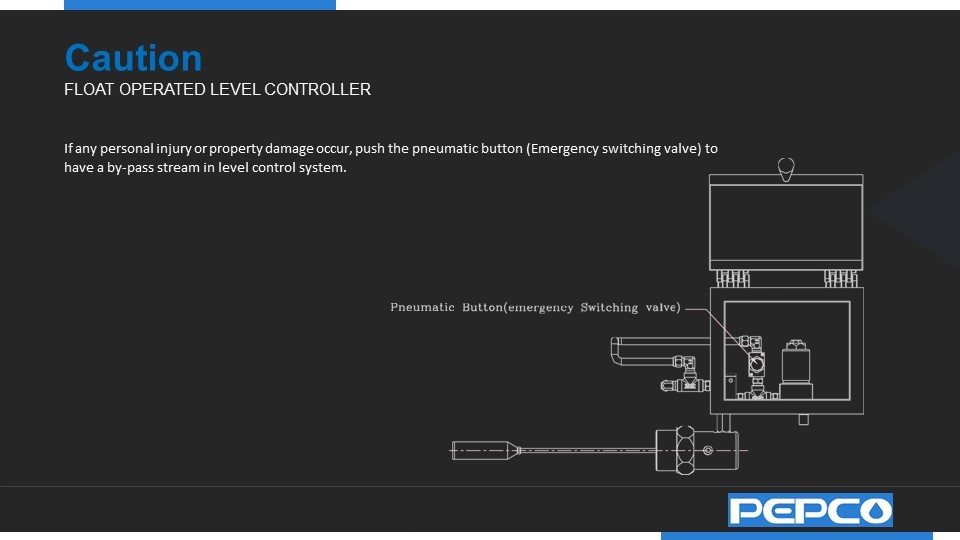

Warning

Only trained personnel should install or service a liquid level control pilot or the devices to which it is connected. Pilots and other control devices should be installed, operated, and maintained in accordance with international codes and regulations, manufacturer’s instructions, and proven best practices. Personal injury, equipment damage, property damage, leakage or bursting of pressure-containing parts may result if the pilot is overpressure or installed where service conditions could exceed the limits given in the Specifications section. Overpressure protection should also be provided if the pilot inlet pressure may exceed the safe working pressure of the equipment downstream. To avoid injury or damage, install pressure-relieving or pressure limiting devices to prevent service conditions from exceeding those limits. Consult the appropriate code, regulations, or standards.

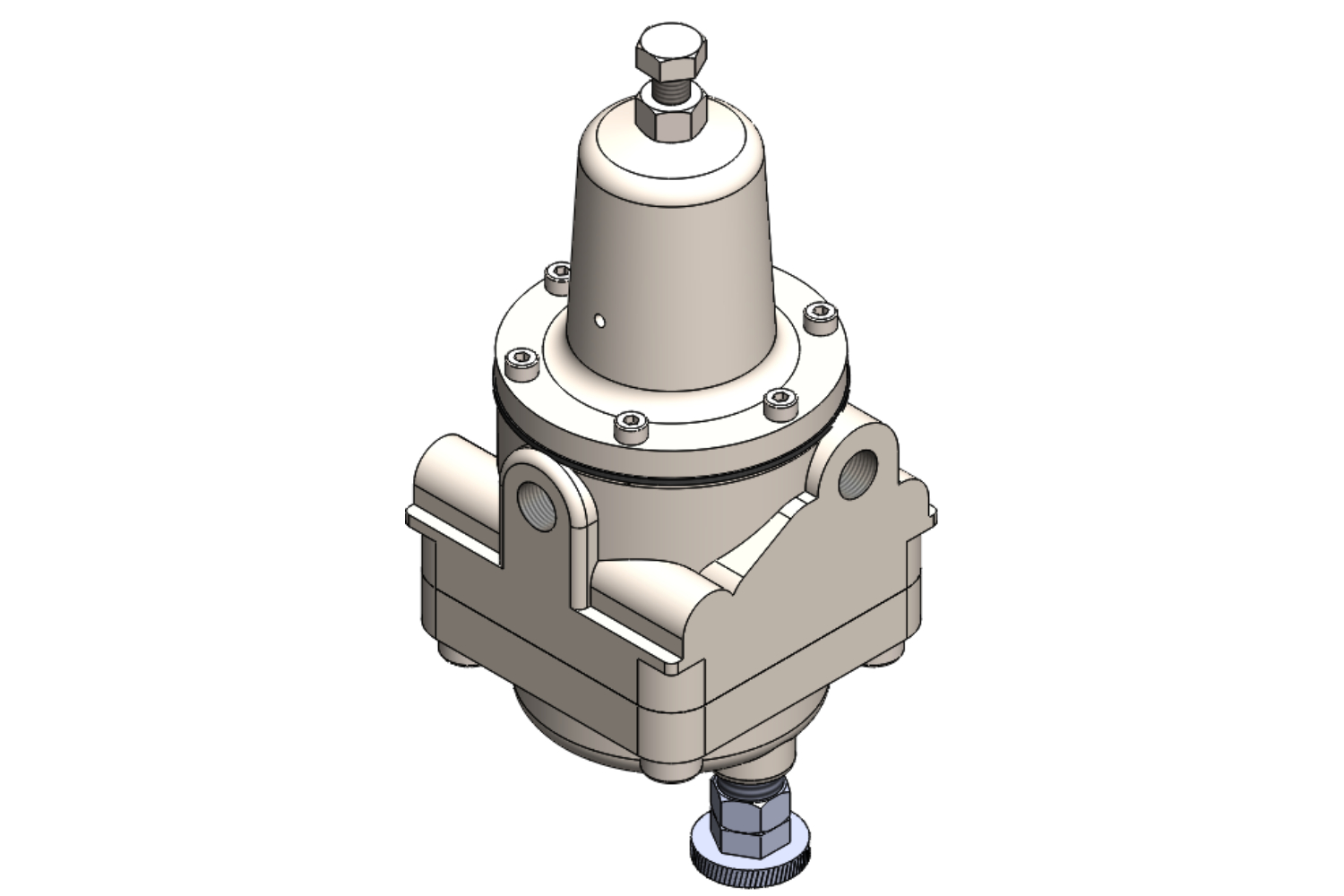

Installing The Level Control

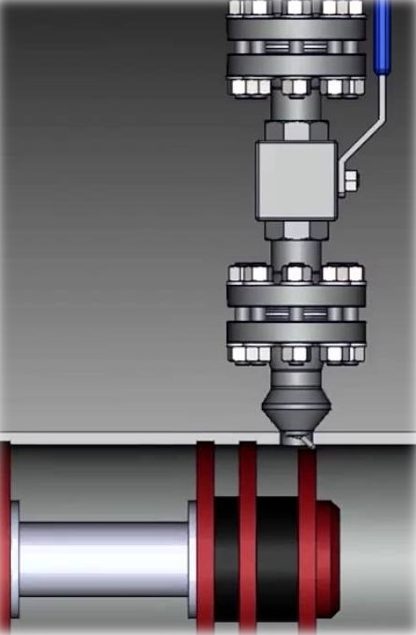

NPT CONNECTION: Apply TFE tape or pipe compound to the male threads of the threaded body. Tighten sufficiently to seal the threads. Use a wrench on the flats of the body. Do not use the pilot case to tighten the connection. Remove the plastic plugs from the 1/4” NPT openings.

tubing (not provided) must be installed:

SUPPLY – Connect to a source of clean, dry instrument gas.

OUTPUT – Connect to the diaphragm housing on the control valve being operated.

Contact Us

Contact Us Engineering Group

Engineering Group

Creative Strategy

Creative Strategy Download

Download