ABOUT EQUIPMENT

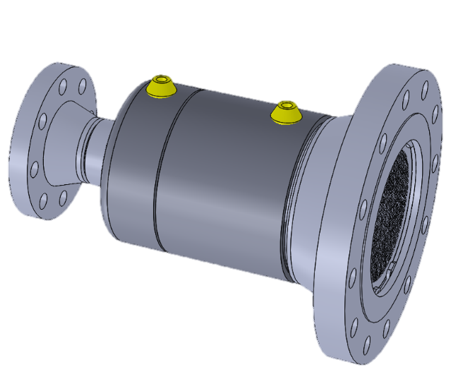

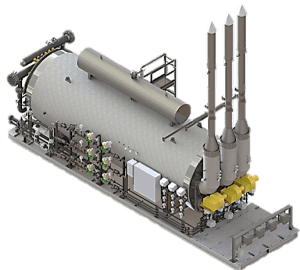

IN-LINE SILENCER

If the amount of sound in human surroundings is more than the standard limit, it becomes noise pollution. Noise pollution increases blood pressure, heartbeat, anxiety, mental stress, sleep disorder and hearing loss.

INTRODUCTION

If the amount of sound in human surroundings is more than the standard limit, it becomes noise pollution. Noise pollution increases blood pressure, heartbeat, anxiety, mental stress, sleep disorder and hearing loss.

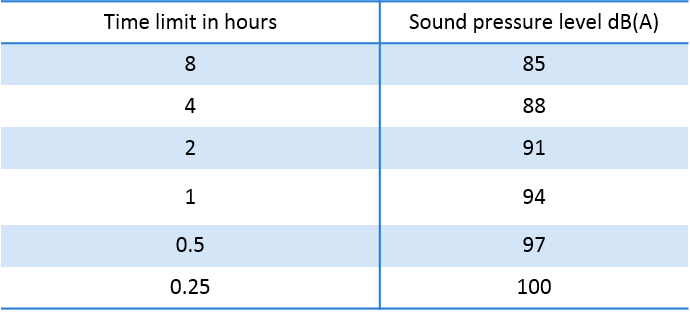

According to the occupational noise standard of Iran’s Ministry of Oil (IPS-G-SF-900) and the occupational noise guidelines of the American National Institute of Occupational Safety and Health (NIOSH), the time of exposure to work environments that have noise pollution is as described in the following table:

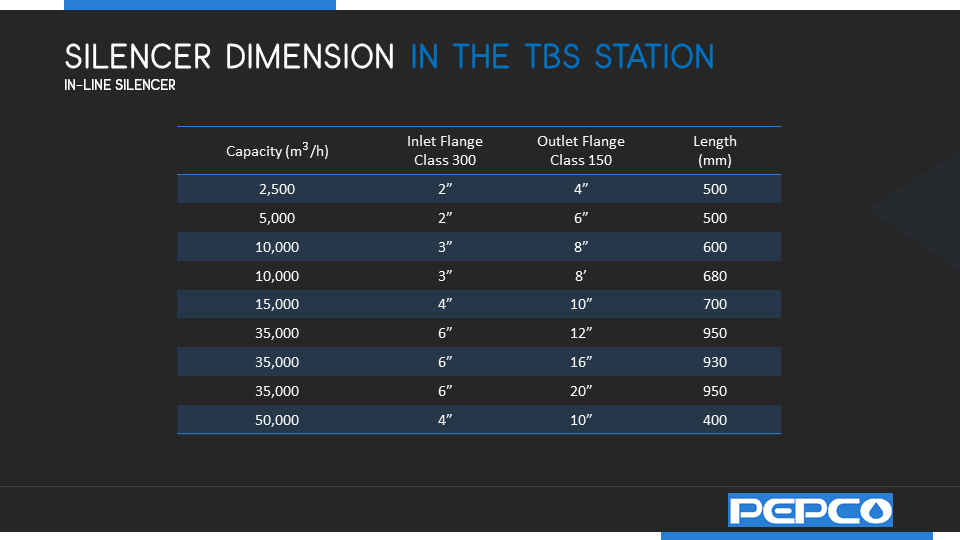

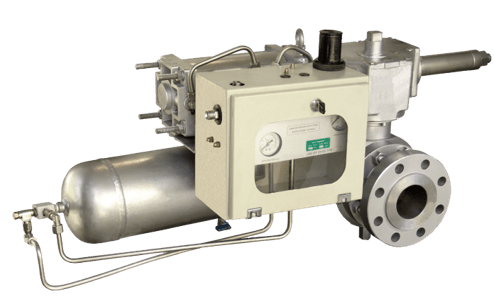

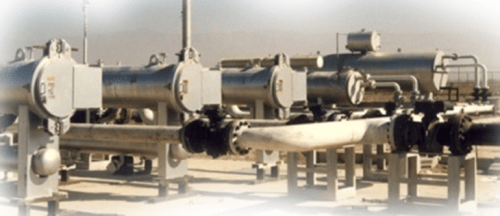

According to the table, the permissible sound level for 8 working hours is 85. In the TBS gas pressure reduction stations, due to the sudden drop in gas pressure, severe noise pollution is created, which should be controlled. The silencers of TBS stations are designed and produced based on ASME standards and in accordance with the existing operating conditions in Iran. One of the important features of these products is the ability to reduce the noise of the station to a significant and impressive level. This category of silencers with good performance can solve most of the problems caused by noise pollution. In the design of these products, in order to measure the pressure drop of the silencer on the body of the silencer, two numbers of thermocouples are embedded, which can measure the difference between the beginning and the end of the silencer pressure by means of the necessary connections and the pressure gauge. Also, this product is designed in such a way that it dampens severe pressure fluctuations and as a result prevents the regulator from opening and closing.

Acoustic features of the inline silencer

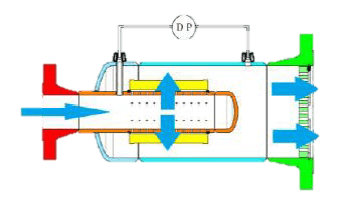

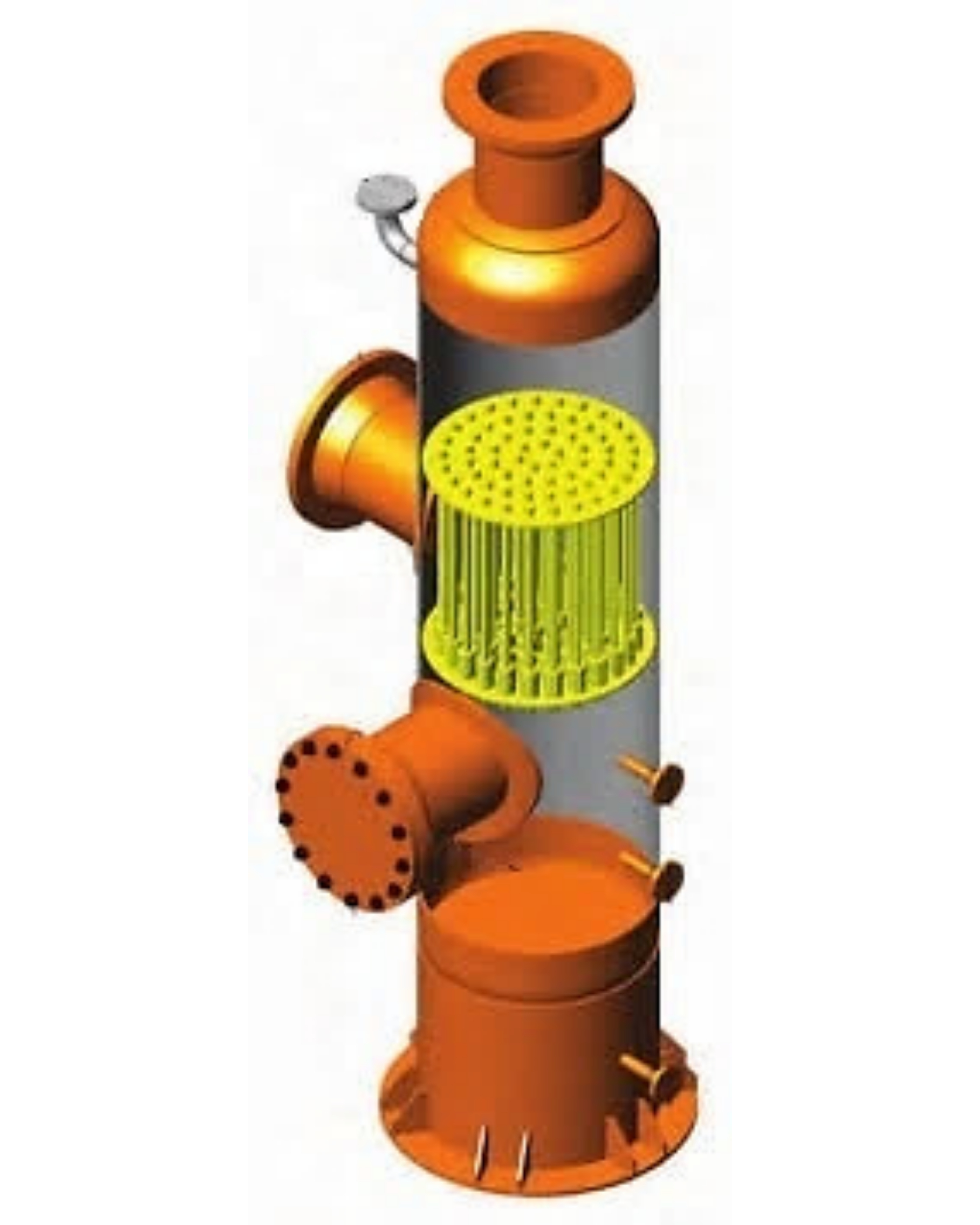

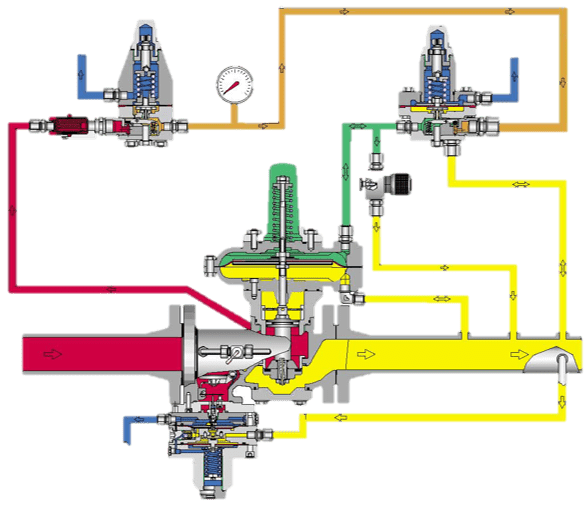

The reason for noise in pressure reduction stations is the pressure drop created in the regulator. By placing the silencer after the regulator, it controls disturbances and noise. The silencer usually has a pressure drop, but the regulator automatically compensates for this pressure drop because the pressure sensor of the regulator is located after the silencer. The silencers manufactured by this company are of the passive type, which reduces the sound with the help of two factors of reflection and absorption, as a result, two parts, a diffuser and a cartridge, are necessary to achieve this goal. These parts inside the silencer body are installed and arranged in such a way that they have optimal acoustic performance.

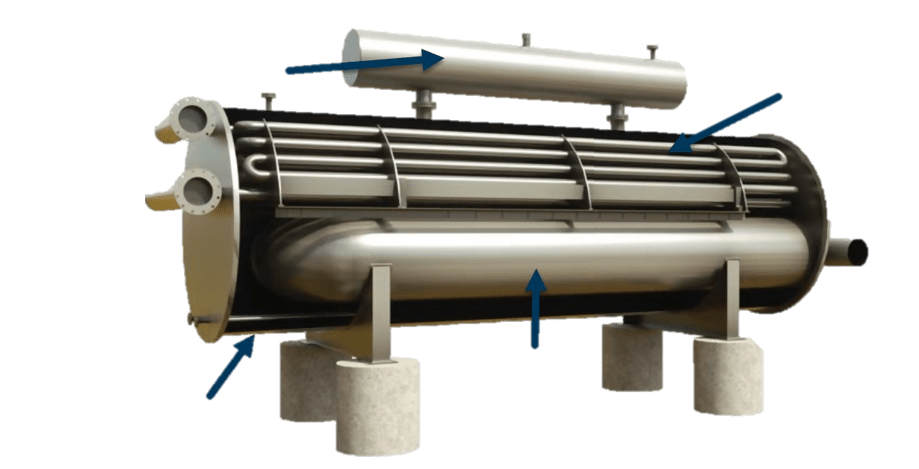

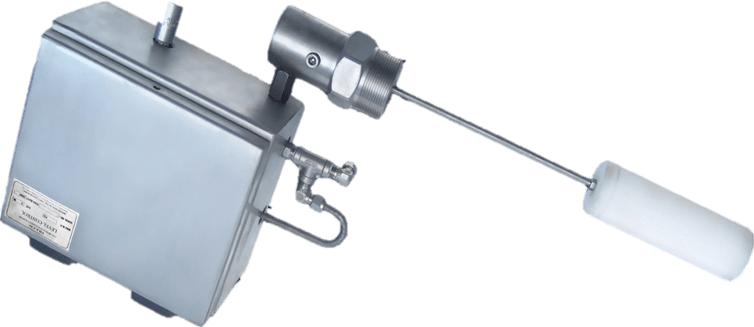

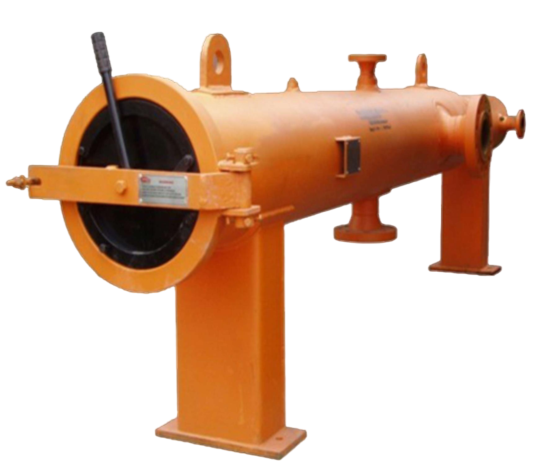

THE MAIN PARTS OF THE INLINE SILENCER

The online sketches of the company consists of four main parts, each of which has a specific task in reducing and controlling the sound produced by the station.

Main body

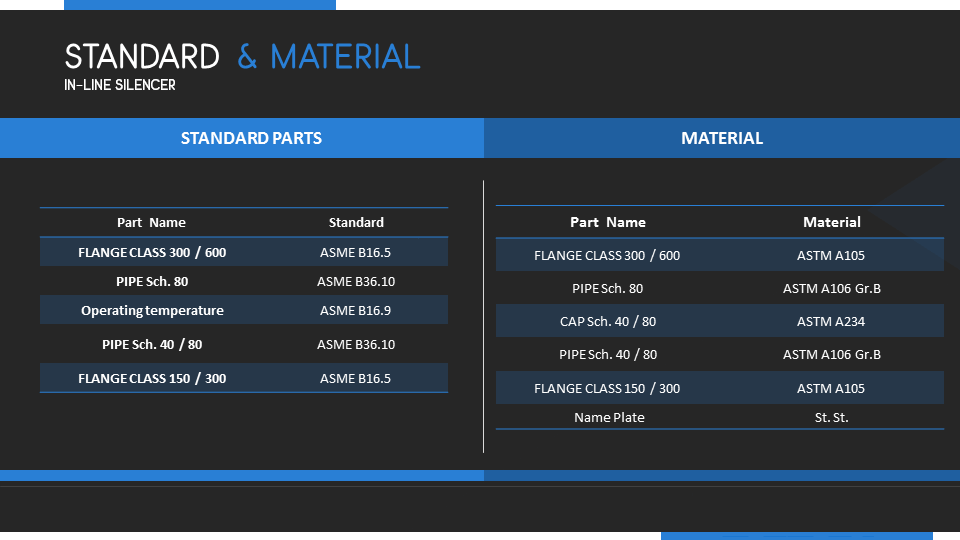

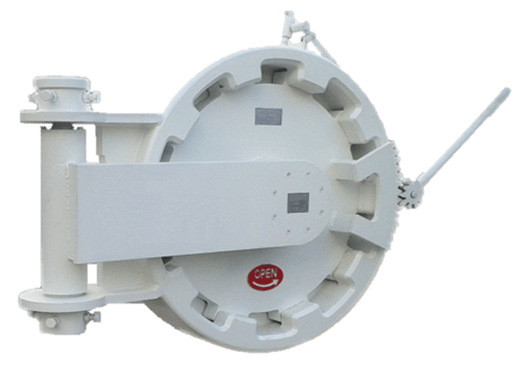

The main body of the Silencer is carbon steel, which includes an inlet flange, cap, nipple and output flange.

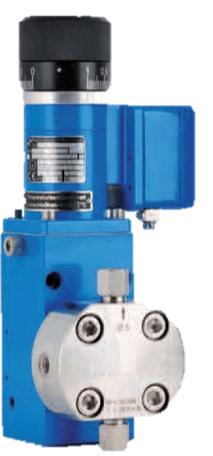

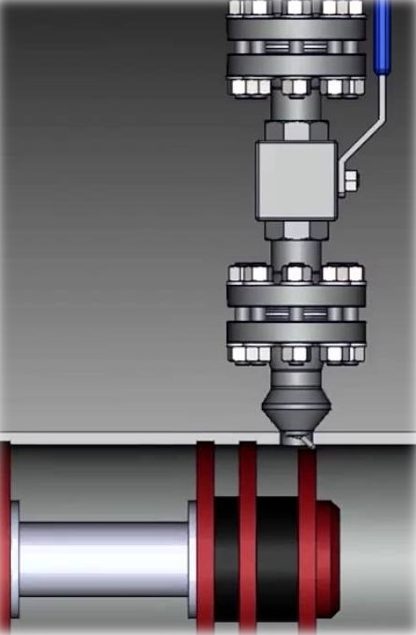

Diffuser

A carbon steel tube is used and the current is directed directly after the regulator. The task of the diffuser is to reduce the amount of sound and change the frequency of the current produced.

Cartridge

It is a set of networks that control the production of gas through the production of gas through the flow of gas.

Conditioner

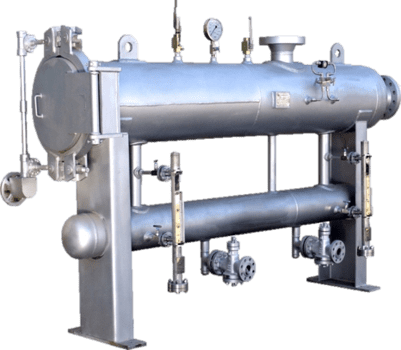

The “U” Shaped fire tube is located in the lower half of the shell fully immersed in the water bath. Fuel gas is burned within the fire tube releasing heat through the wall of the fire tube to the water bath maintaining temperature up to 1900F (880C). The heated water bath then transfers heat through the tube wall to the fluid flowing through the process/flow coil or a series of tubes which are located in the upper half of the vessel. Typical fluids to be heated are well streams, oil, natural gas etc. The fire tube gas supply is controlled by a temperature controller in order to maintain the required bath temperature for the actual inlet and/or outlet conditions.

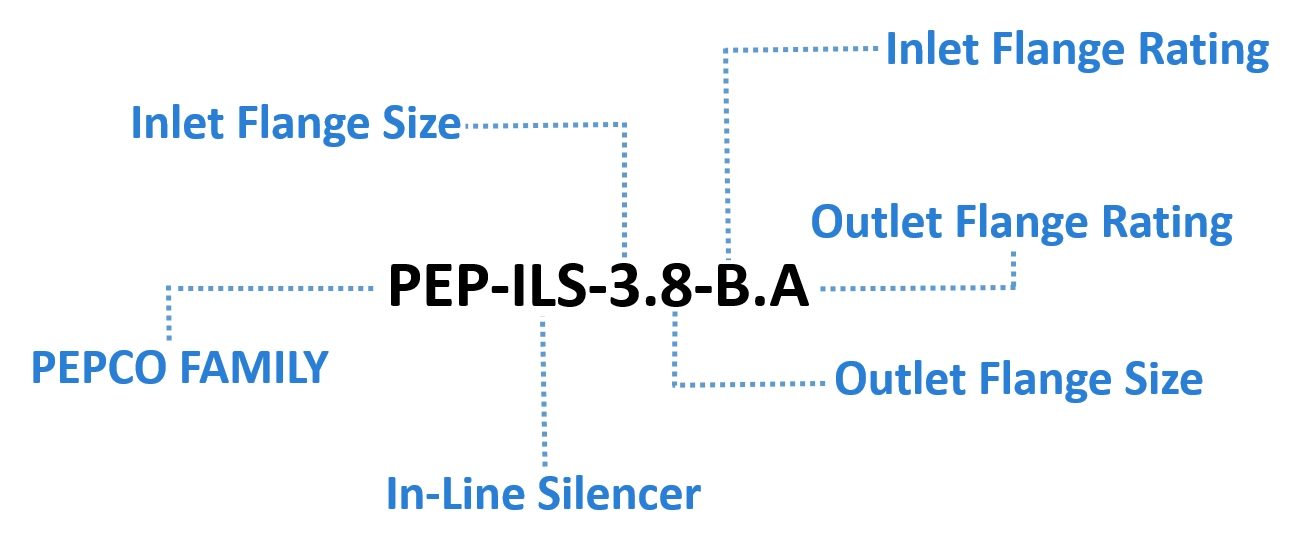

TYPE DESIGNATION

SILENCER FUNCTION

By installing the silencer immediately after the regulator, the gas enters the diffuser. The gas inside the diffuser enters the cartridge by turning 90 degrees and passing through the holes of the diffuser, and then enters the flow stabilizer section, which includes a conditioner. After the gas passes through the constant flow conditioner, it enters the continuation of the pipeline.

Contact Us

Contact Us Engineering Group

Engineering Group

Creative Strategy

Creative Strategy Download

Download