ABOUT EQUIPMENT

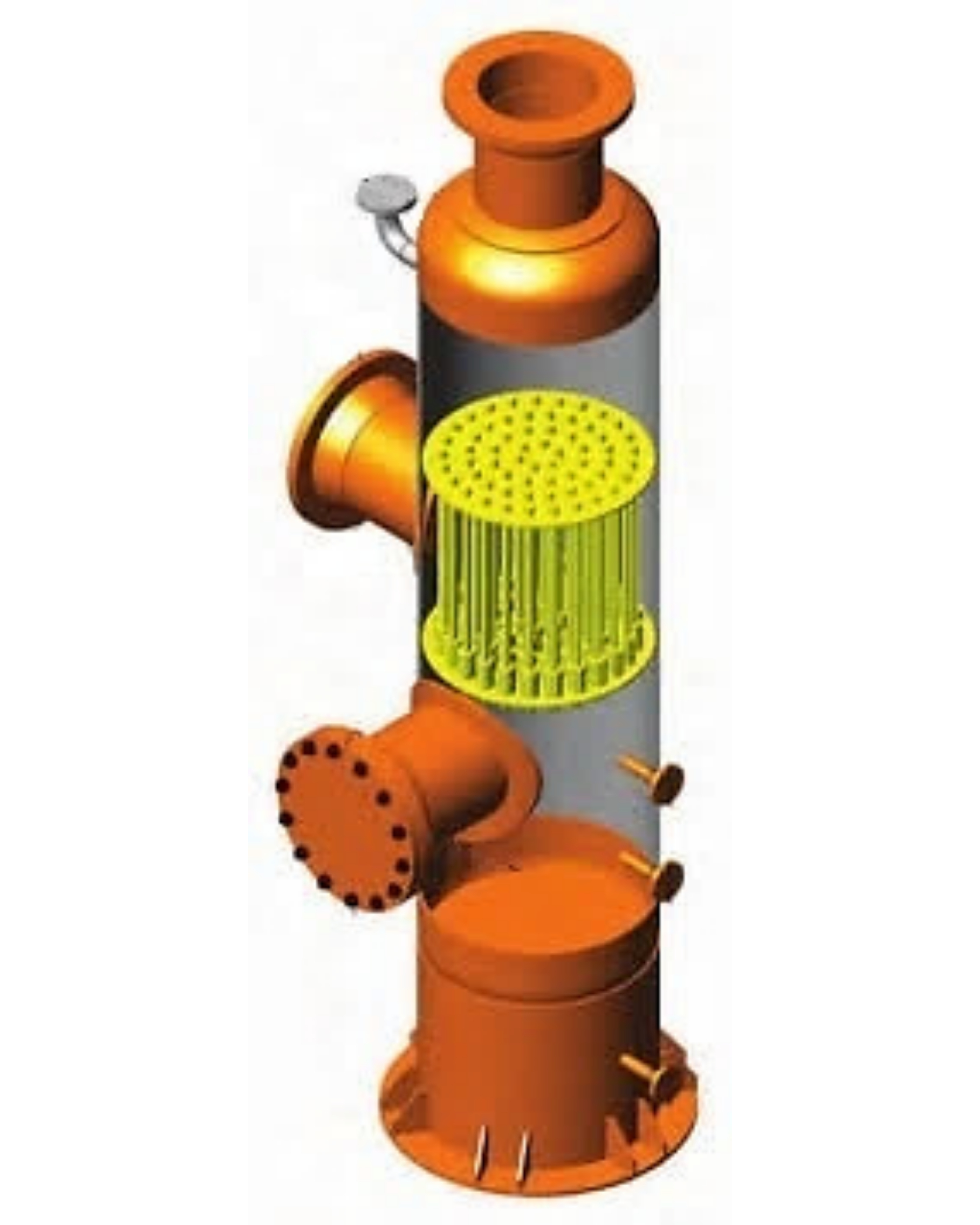

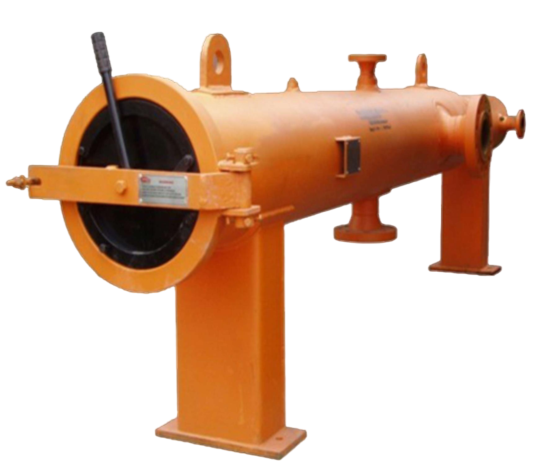

MULTI CYCLONE GAS SCRUBBER

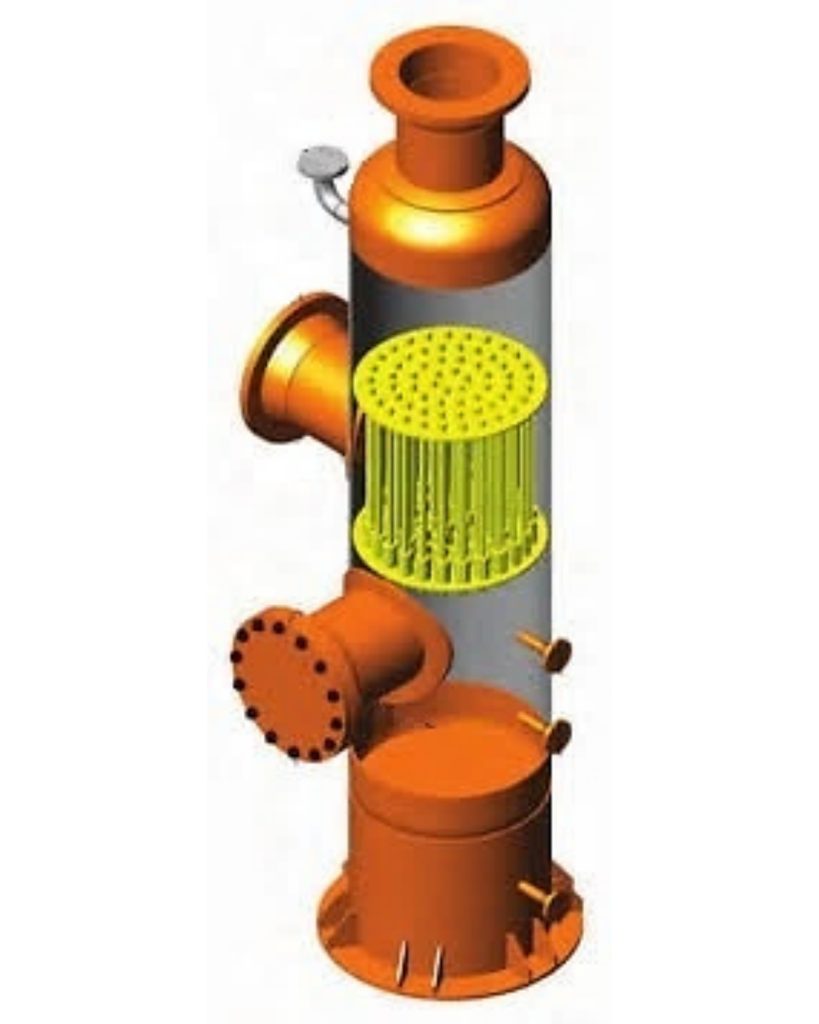

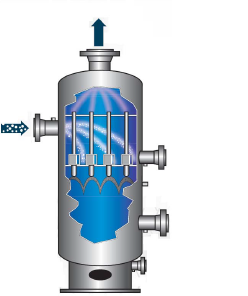

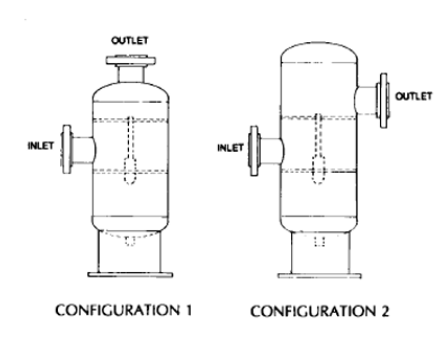

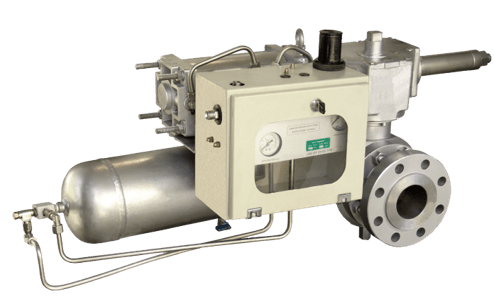

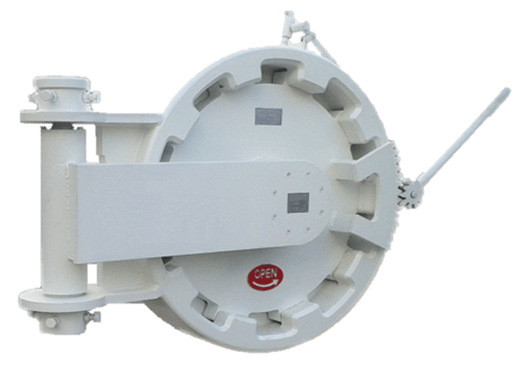

The Multi-cyclone Gas Scrubber is a high-capacity separator designed for removing liquids and/or solids from gas flows with a minimum pressure drop.centrifugal force to separate solids and liquid droplets from the gas phase based on density difference. Very high G forces are achieved which allows for efficient removal of small droplet sizes. The main advantage of cyclonic mist extractors is that they provide good removal efficiency at very high gas capacity. This generally allows for the smallest possible vessel diameter for a given gas flow. Cyclonic mist extractors are often used in low liquid load gas scrubbing applications, and for high pressure gas-liquid separation.These devices are proprietary and cannot be readily sized without detailed knowledge of the characteristics of the specific internals. A typical centrifugal separator is shown in above picture.

Typical Application

Distribution systems

-

Mainline transmission stations

-

Gas gathering systems

-

Petrochemical plants

-

Slug catching

Absorption processes

Reciprocating compressor protection

Principles of Operation

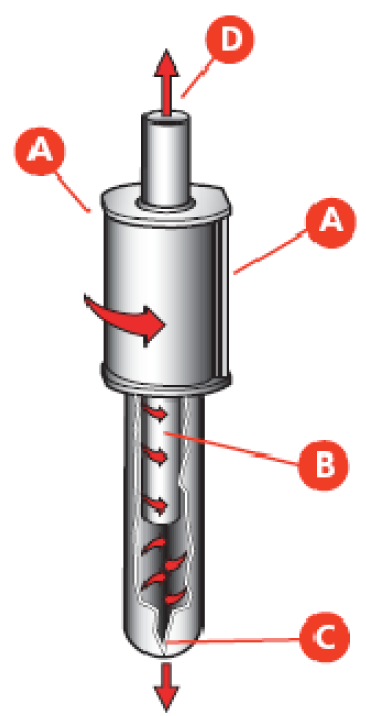

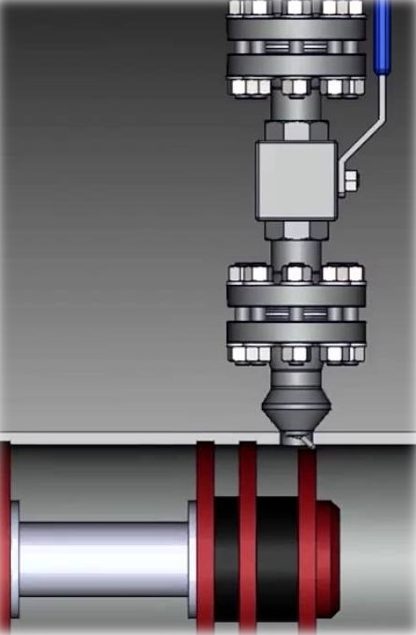

Multi-Cyclone Scrubbers use centrifugal force to effectively remove solid particles and liquids from gas without moving parts. (A) Contaminated gas enters the Cyclone Tube tangentially.

(B) The tube housing forces the gas into a cyclonic flow pattern. Centrifugal force throws the solids and liquids against inner cyclone tube wall.

(C)Solid and liquid particles drain down the cyclone tube walls and collect at the bottom.

Disk Holder Assembly: Aluminum and nitrile (NBR) Stainless steel and Fluorocarbon (FKM)

(D) Clean gas flows down and then up through the center annulus and exits at the top.

Multi-Cyclone Benefits

High-efficiency liquid and solid removal

-

A wide range of flows

-

Intermittent flow spikes capacity

-

Maintenance free

-

High liquid handling capacity

Constant ΔP regardless of loading

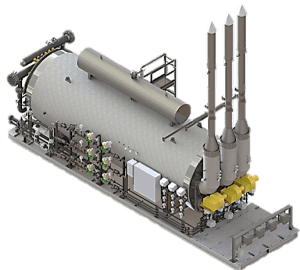

Two Stage Multi Cyclone Gas Scrubber

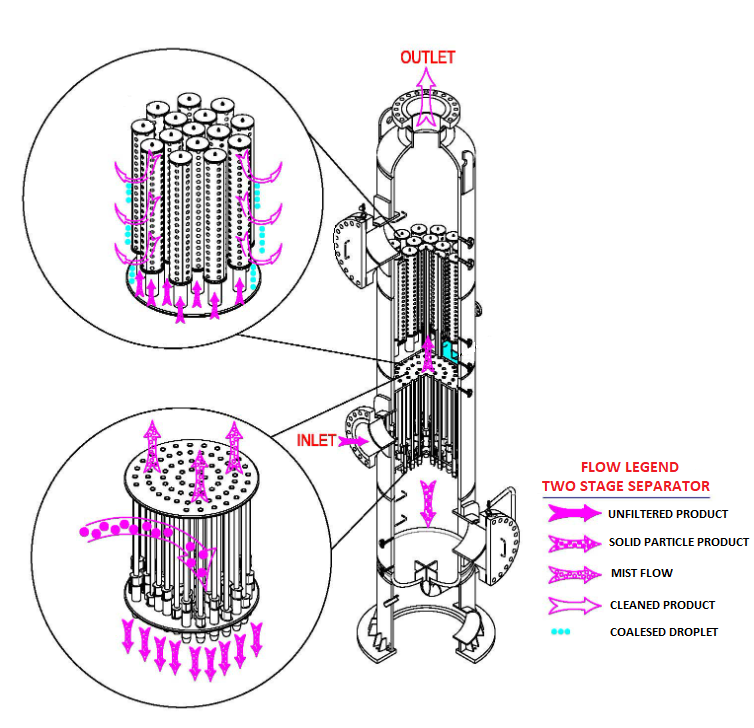

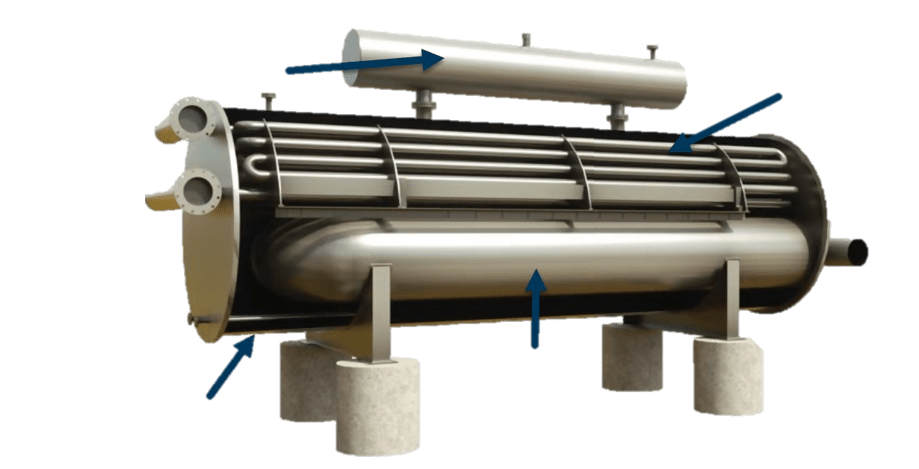

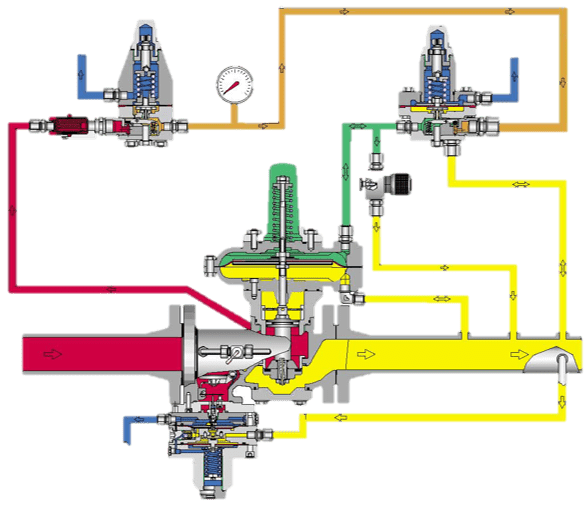

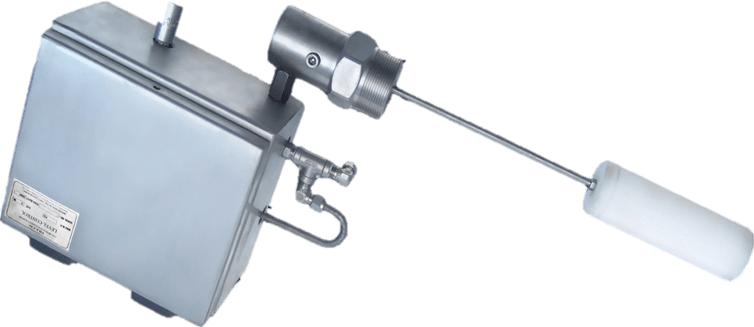

This type of scrubber has two separation stages. In the first stage, gas enters the cyclone tubes and particles are separated from the gas under the influence of centrifugal force. In the second stage, very small droplets that have been able to pass through the first stage with gas enter the coalescer elements and are coalesced into larger droplets.

The ability to efficiently separate both solid and liquid particles at high capacities is one of the advantages of using this type scrubbers. The below figure shows how two-stage scrubbers work.

Features

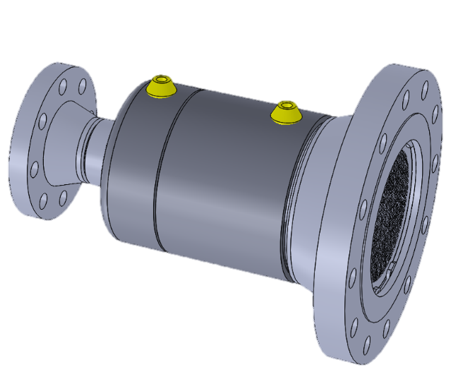

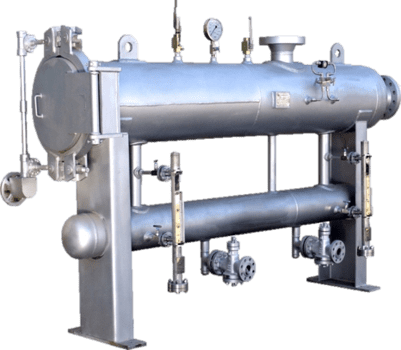

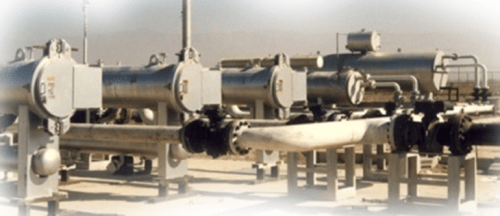

PEPCO Scrubbers are available in standard inline Configuration-1 or side inlet-top outlet Configuration-2 as shown below. Other orientation may be used to suit client’s piping arrangements.

Solid Removal Fficiencies

100% of 8 Micron Particles

-

99% of 6-8 Micron Particles

-

90% of 4-6 Micron Particles

-

85% of 2-4 Micron Particles

Liquid Removal Efficiencies

outlet gas will contain less than 0.1 US gallon of entrained liquid per million standard cubic feet of gas through the separator (13Liters / Million SCM)

-

9100% of droplet 8 Microns in diameter and larger

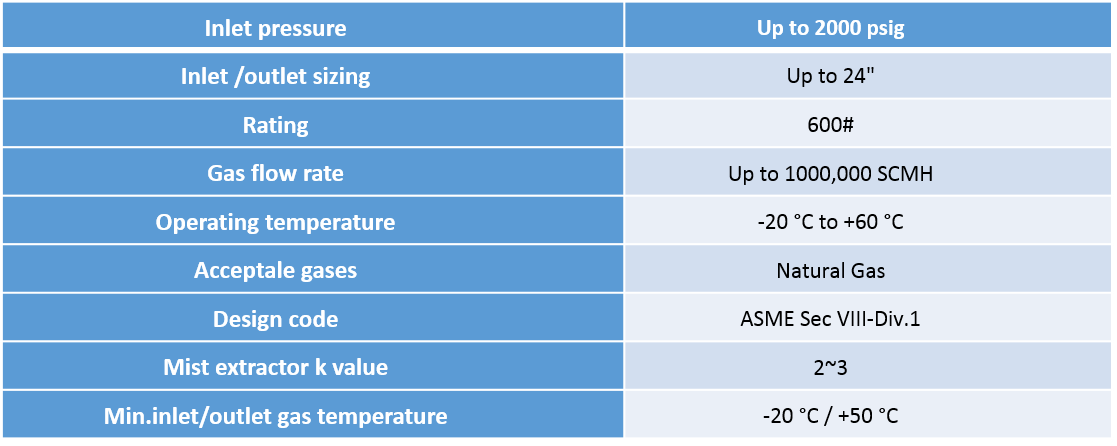

Technical Specifications

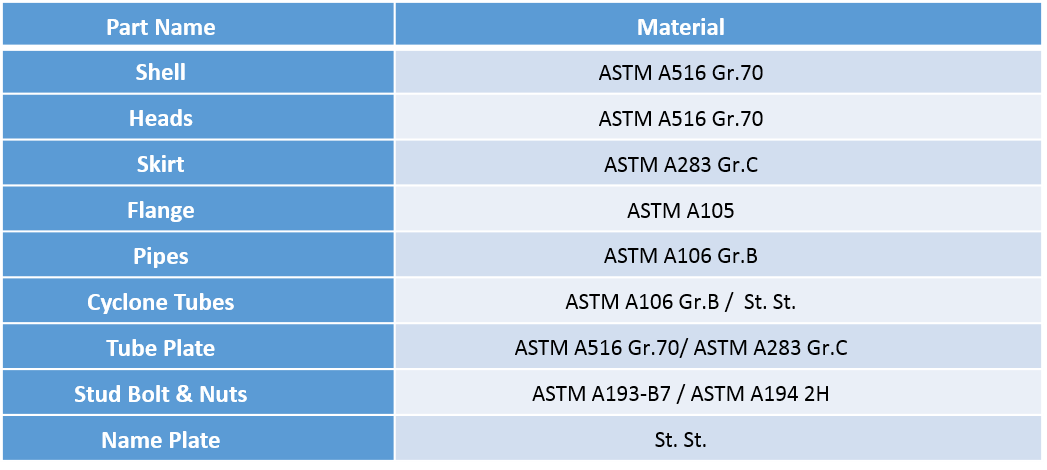

Material

Contact Us

Contact Us Engineering Group

Engineering Group

Creative Strategy

Creative Strategy Download

Download