ABOUT EQUIPMENT

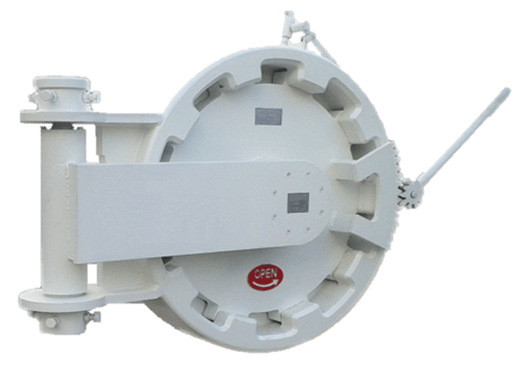

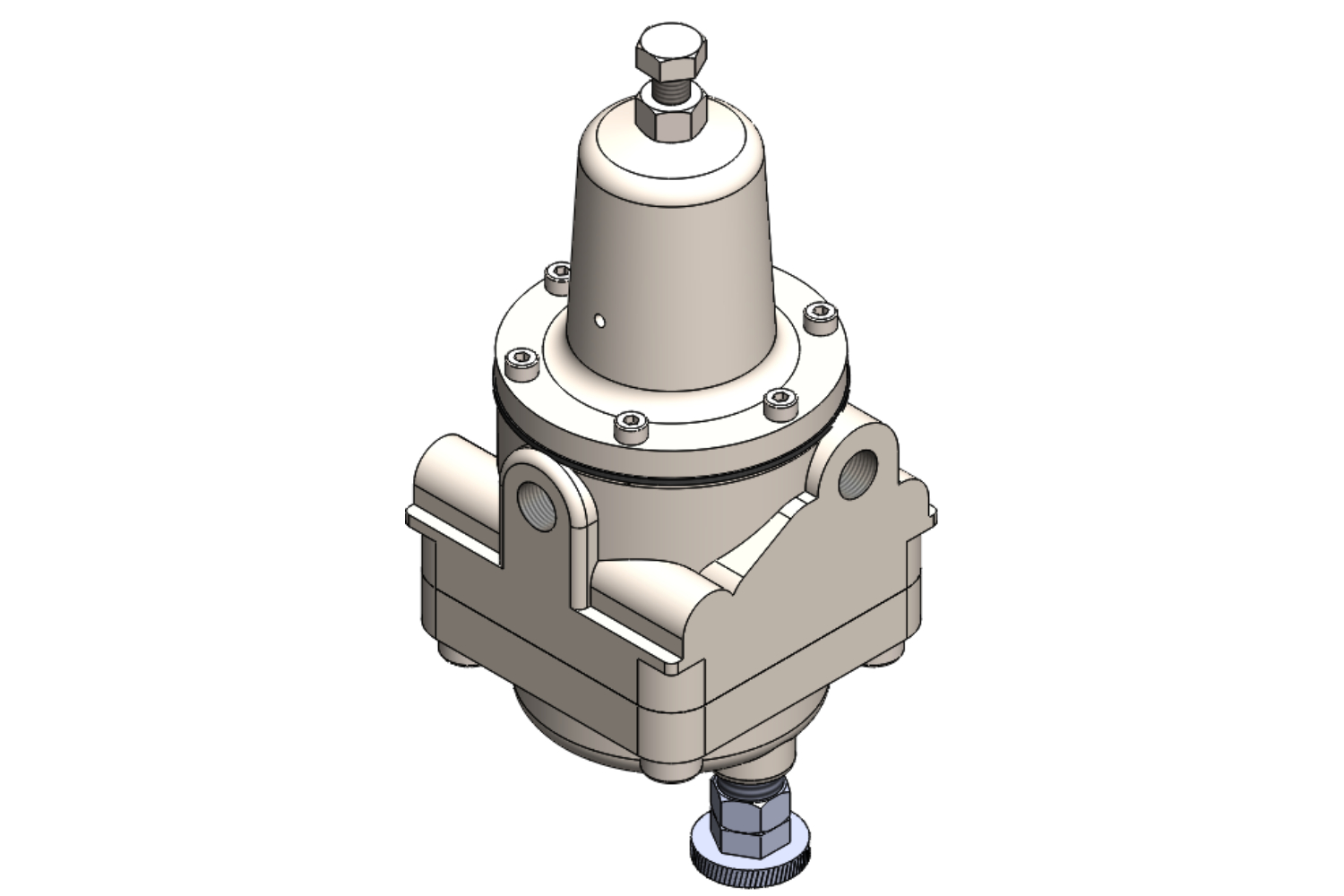

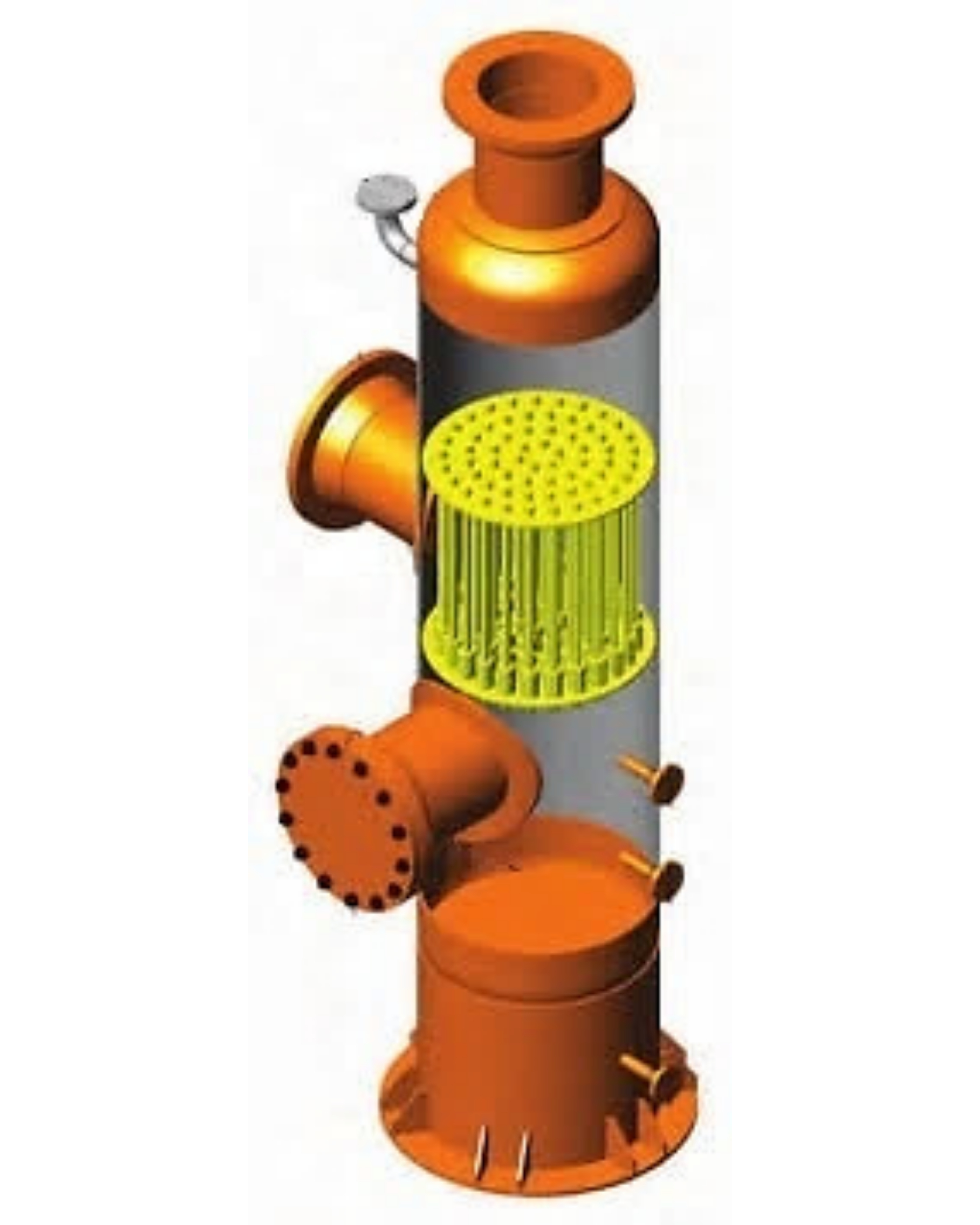

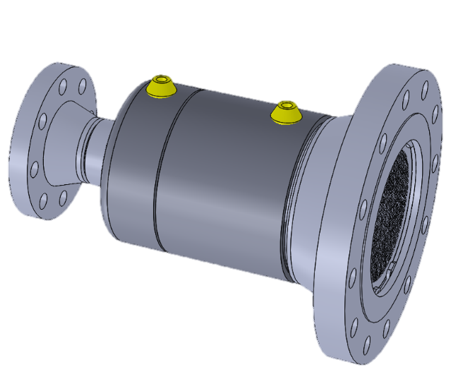

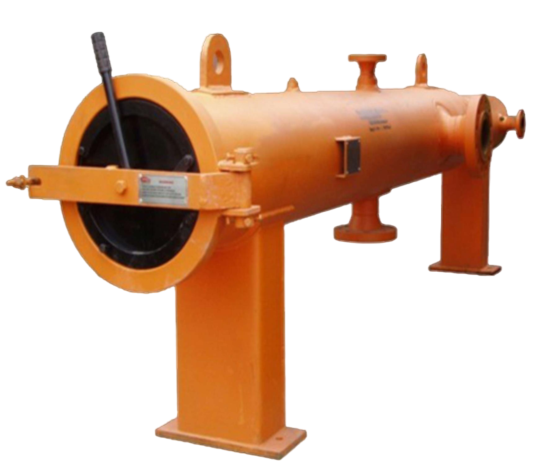

QUICK OPENING CLOSURE BAYONET TYPE

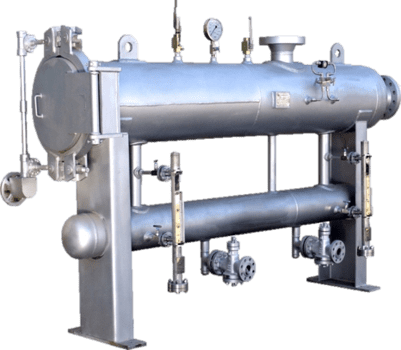

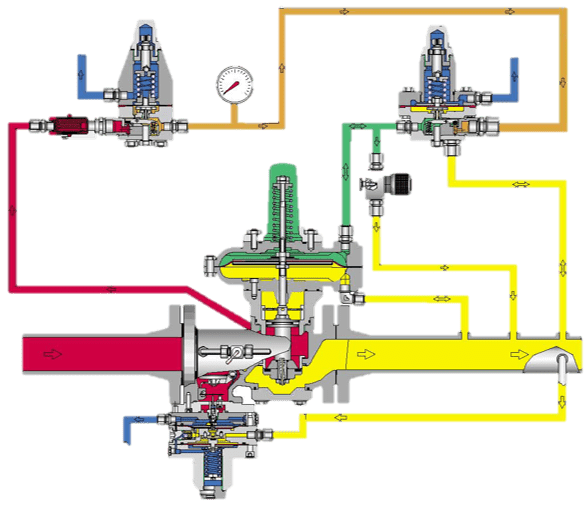

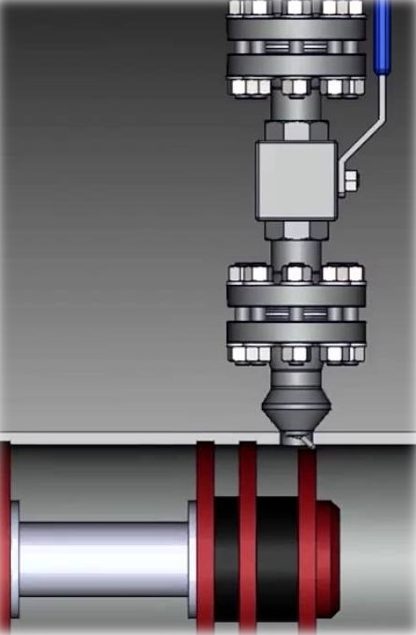

The Bayonet Closure in general, it is intended for larger vessel sizes and higher pressure applications. It is robust and can be manufactured in a range of materials from carbon steel to stainless steel and even duplex to suit any pipe or pressure vessel material. In line with UG-35 requirements the closure comes with a minimum of two safety features preventing the closure from being opened when the vessel is still pressurized.

ABOUT EQUIPMENT

The Bayonet Closure in general, it is intended for larger vessel sizes and higher pressure applications. It is robust and can be manufactured in a range of materials from carbon steel to stainless steel and even duplex to suit any pipe or pressure vessel material. In line with UG-35 requirements the closure comes with a minimum of two safety features preventing the closure from being opened when the vessel is still pressurized.

The PEPCO closures are engineered, designed and built according to the most stringent international standards applicable to pressure vessels for oil, gas and petrochemical industry in general, but the revolution is represented by integrated services in order to ensure the best performance during throughout the life cycle of the product. The possibility of being disassembled through the action of a single bolt, enables the installer to handle the device without jeopardizing the functionality of the critical parts, such as might happen in the case of heat treatments or other operations more or less invasive. Similarly, the maintenance operations are greatly facilitated.

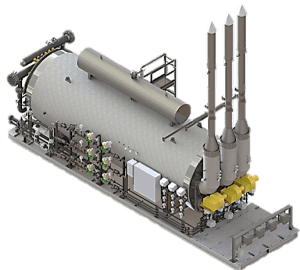

Closures provide horizontal or vertical access to pipeline Pig Traps, Filters, Separators, or any pressure vessel in seconds.

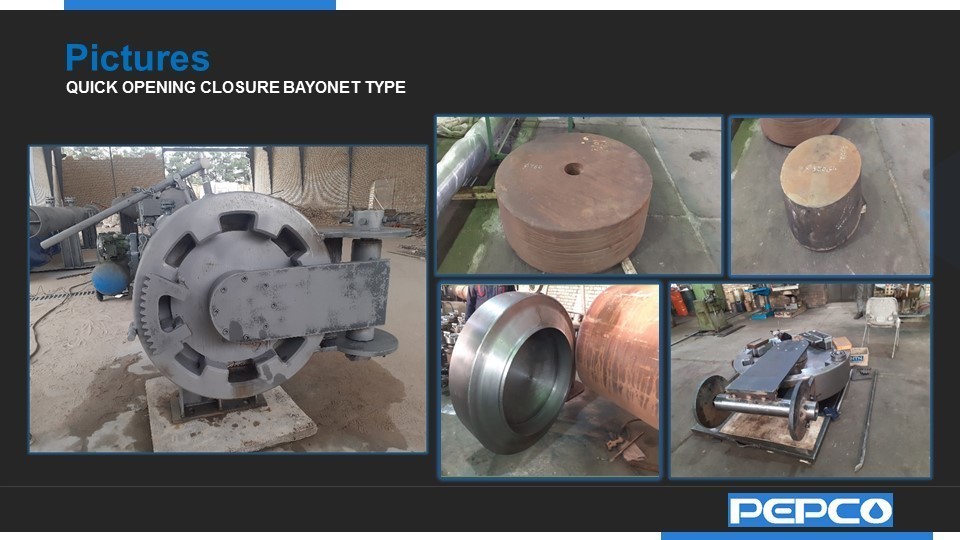

Design, Fabrication and Features

PEPCO Design and Engineering team manages and controls the whole process carefully from the initial design of each closure to make sure its design meet project requirements right through to final delivery to PEPCO’s clients.

Design Fabrication Features PEPCO Quick Opening Closures are fabricated from ASTM A-105N or A-350-LF2 and forgings or ASTM A-516-70 plate. For special applications, PEPCO closures can be furnished in alloy materials, as well as weld overlaid. The PEPCO closure is also available in MS ratings, or may be custom designed under ASME VIII, Div. 1, Appendix 24, Div. 2, or other applicable construction code authority.

Quick Opening Closures are manufactured from ring rolled forgings that permit larger closure designs and are not limited to standard diameters. Closures can be designed for the customer’s exact operating requirements, rather than using the (often heavier than required) ANSI series flanges.

Engineering department of PEPCO, relies on the most advanced computer software for:

- Thermal Design

- Mechanical Design

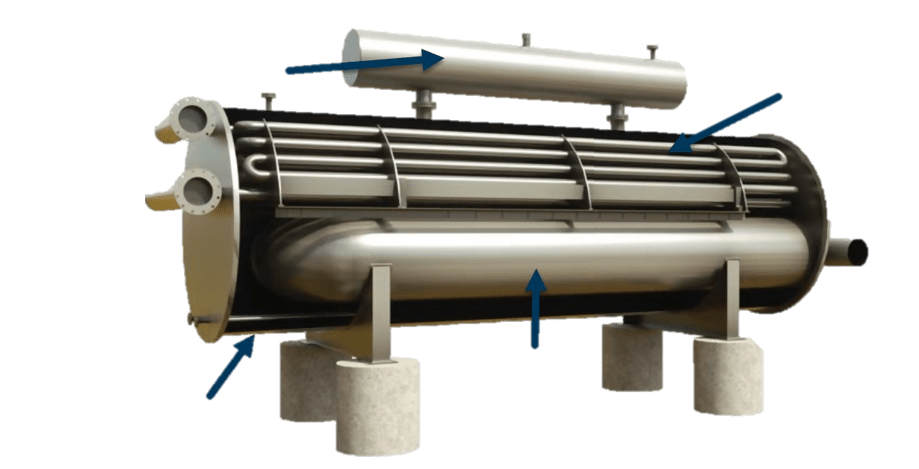

Horizontal

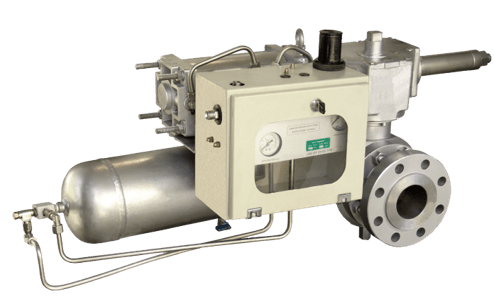

For horizontal applications, the PEPCO closure is supplied with a heavy duty, double pivot hinge arrangement that fully supports the weight of the closure door, minimizes the swing radius and insures repetitive operation.

Vertical

For vertical operation, the PEPCO closure can be supplied in several designs to suit the requirements of the customer and to suit their site needs.

Vertical closures can be supplied with lifting eyes only to permit removal with client supplied equipment. Options for davit arms using simple screw jack, chain hoist or hydraulic are available. The heavy duty davit arm is designed to fully support the weight of the door and provide long term reliable operation A ‘low height’ davit arm is also available on request. For larger diameter closures, where the weight of the door becomes a restraining factor, the door is supplied with three lifting eyes only for use with overhead lifting equipment.

Main Materials

Forged steel hubs with forged or plate doors can be supplied to meet all international material specifications. NACE Standard MR-01-75 / ISO 15156 materials are available.

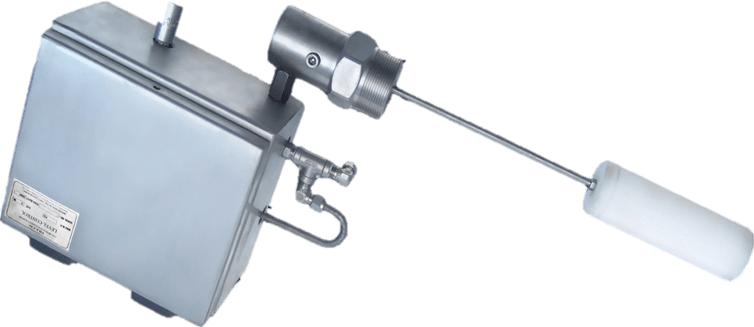

Seal Material

The standard seal materials include Nitrile, Viton and HNBR. Rapid Gas Decompression (RGD) resistant material grades are also available. A range of materials are available to cover a temperature range of -50°C to +210°C (-58°F to +410°F) according to the elastomer specified.

Hydrostatic Testing

Normally carried out as part of the final vessel test but individual closure hydro test can be provided as an option

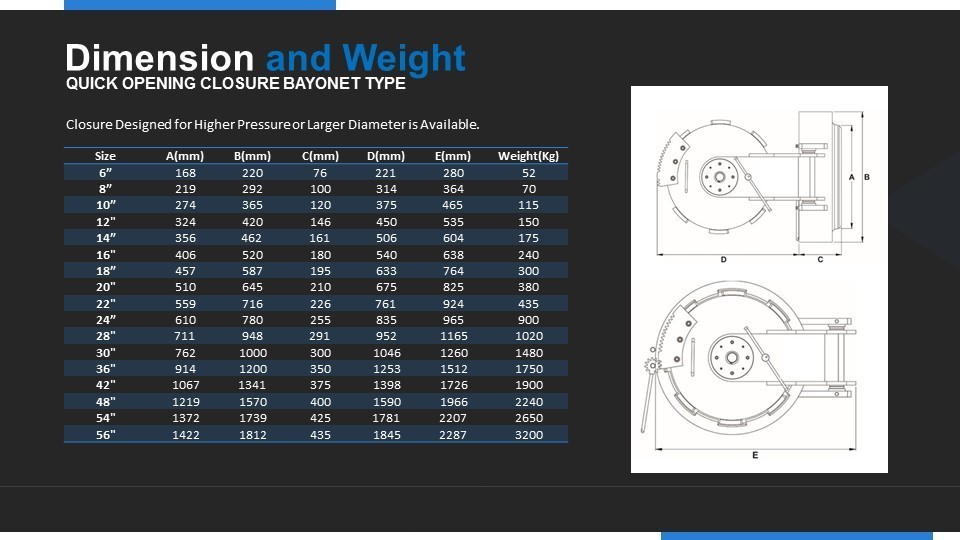

Size and Pressure Rangel

6 inch – 60 inch Diameters with neck hub sized for welding to any diameter and thickness in pressures to ANSI Class 2500.

Non-Destructive Examination

Ultrasonic examination with acceptance levels to ASME VIII Div. 2 Para AM203-2 (C) to (F) on blank forgings and plate (except necks ≤24″ diameter).

New Technology Tested to High Pressure

The PEPCO Quick Opening Closure has been fully tested under extreme high pressure for its performance.

Contact Us

Contact Us Engineering Group

Engineering Group

Creative Strategy

Creative Strategy Download

Download