ABOUT EQUIPMENT

STONE TRAP

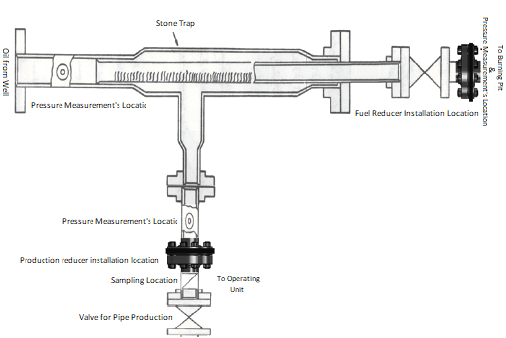

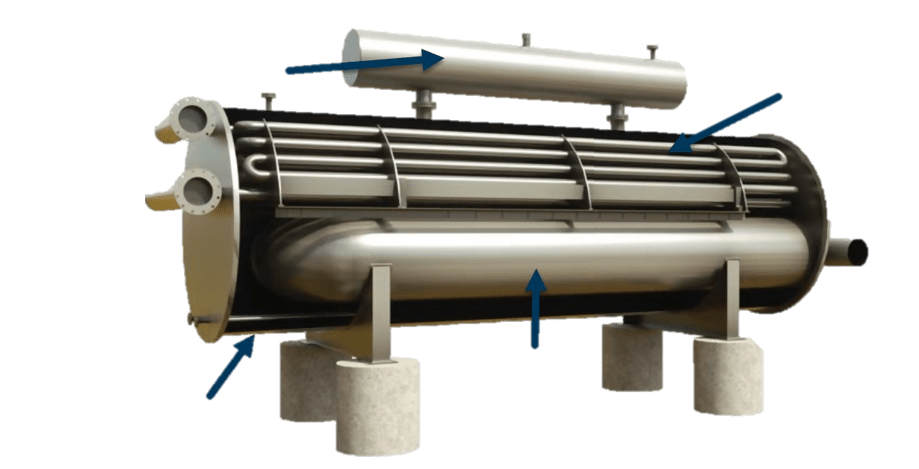

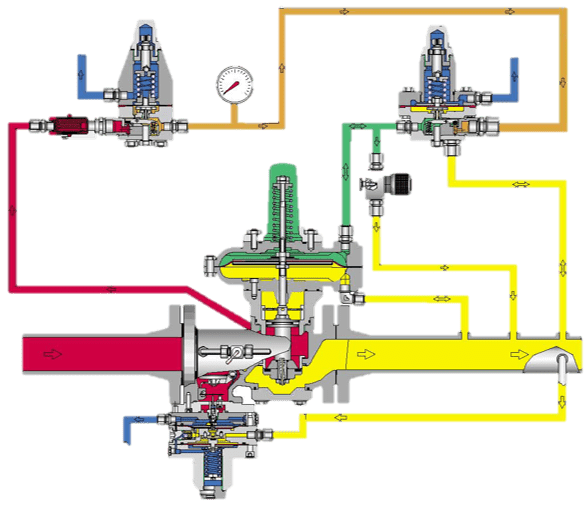

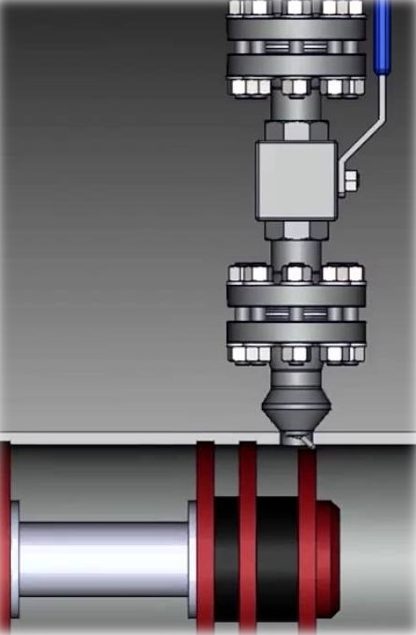

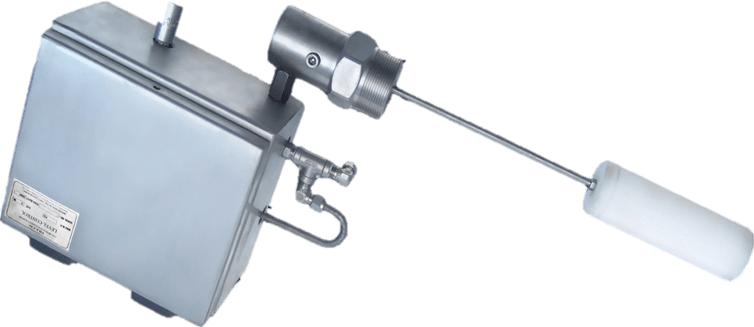

The STONE TRAP is a T-shaped tube located between the production elbow or the bent end pipe, fuel valve and operating valve.

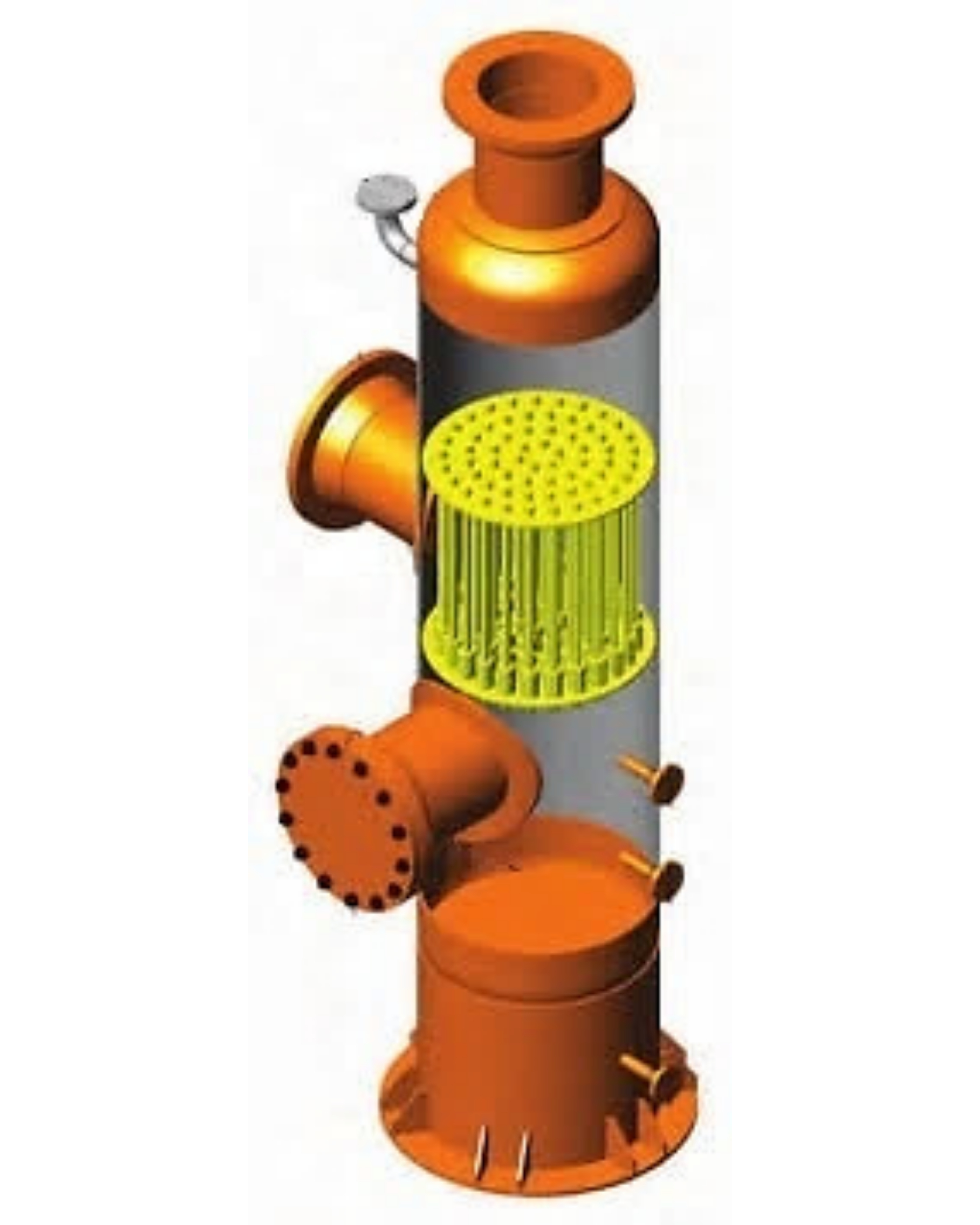

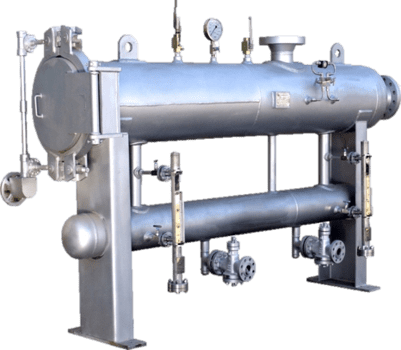

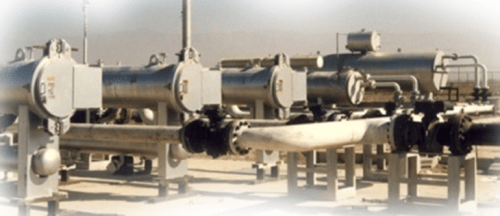

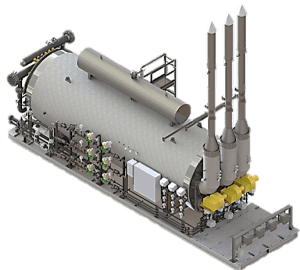

Sand separators are an integral part in protecting downstream production equipment from well-formation sand and/or frack sand.

Stone Trap

Sand separators are an integral part in protecting downstream production equipment from well-formation sand and/or frack sand.

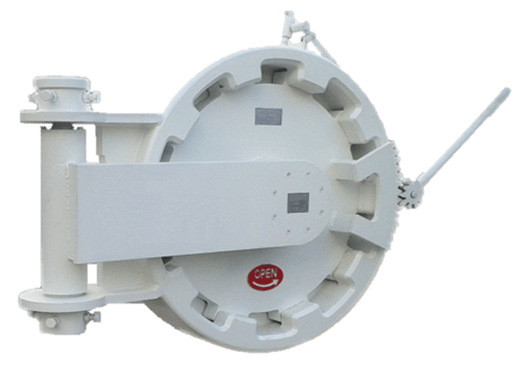

The stone trap is a T-shaped tube located between the production elbow or the bent end pipe, fuel valve and operating valve. In some cases, a gate valve is placed between this pipe and the bent pipe with two ends.Stone traps are used to prevent the passage of stone fragments separated from the reservoir stone or other particles that come out of the bottom of the well with the oil. This device prevents stones from entering the exploitation device.

The pressure difference between the two ends of the stone trap should not be more than 2 to 3 psi. The presence of a pressure difference of 10 to 20 psi between the heads of this device indicates the presence of some sand and other particles along with the oil in the filter parts and the gradual blockage of its grooves follows.

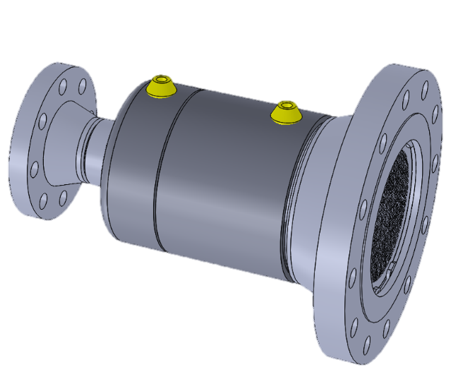

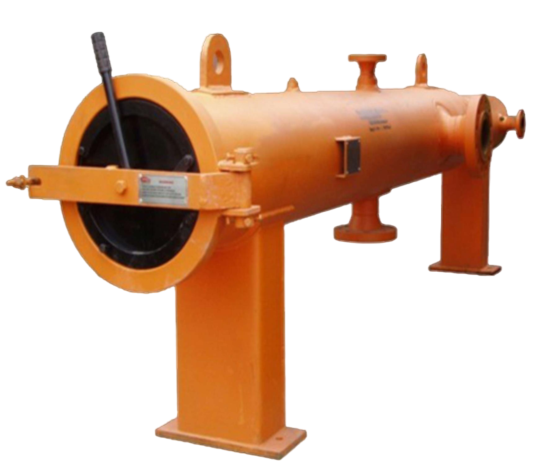

The stone trap is a pipe with a thickness greater than the adjacent pipes and its length is about 1.5 meters or a little more.

According to the picture, before the production pipe is connected to the stone trap and also after the well oil pipe is connected, places for pressure measurement are considered.Sampling locations can also be installed.

The stone trap has two fluid outlets, one is at the end and towards the burning pit, and the other is on its side surface, which is also the connection point of the well’s oil pipe. Wells that are not exploited usually do not have stone traps.

Specification:

Designe code API 6A ,ASME B31.3

-

Nominal Sizes: 4 1/16″, 7 1/16″, 9″

-

Rating: #3000, #5000, #10000

-

Material Class: BB,DD, EE

-

Temperature Rating: U, V

-

Flange material: 45K, 60K, 75K

-

PSL: 1, 2, 3

-

Service: Oil, Gas

-

Suitable for Sour Service, NACE MR0175 ISO 15156

Contact Us

Contact Us Engineering Group

Engineering Group

Creative Strategy

Creative Strategy Download

Download