ABOUT EQUIPMENT

WELLHEAD CONTROL PANEL (W.H.C.P)

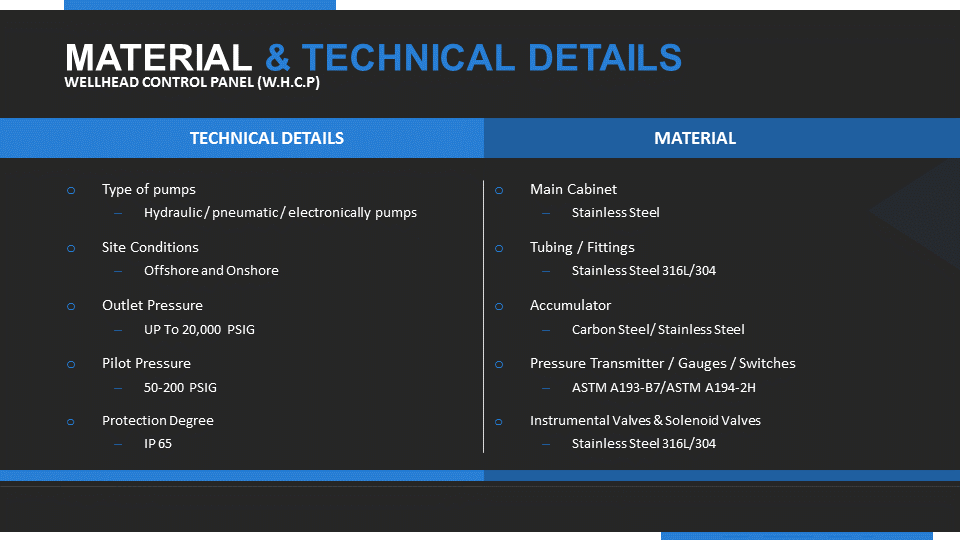

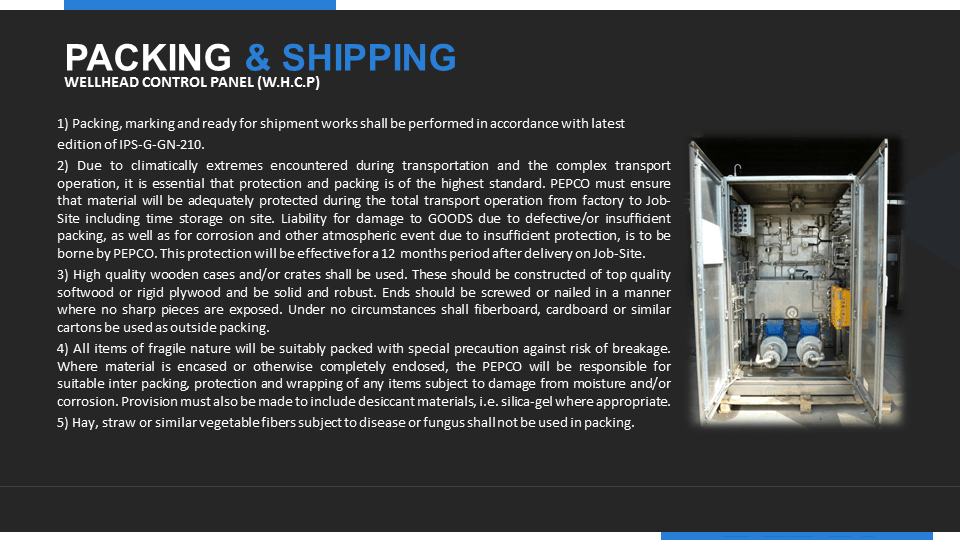

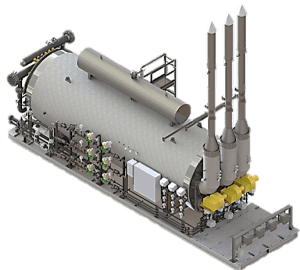

PISHGAMAN ENERGY PAZH CO (PEPCO) systems can provide complete design, supply, installation, commissioning and services for Wellhead process and Control Systems and Power Generation Units. These include pneumatic, hydraulic and electronically automated control and safety shutdown systems for both manned and unmanned off/onshore installations. Our long and proven track record in providing solutions to the offshore oil and gas markets has enabled us to come up with versatile and customized solutions which can withstand hazardous and contemporary environments.

ABOUT EQUIPMENT

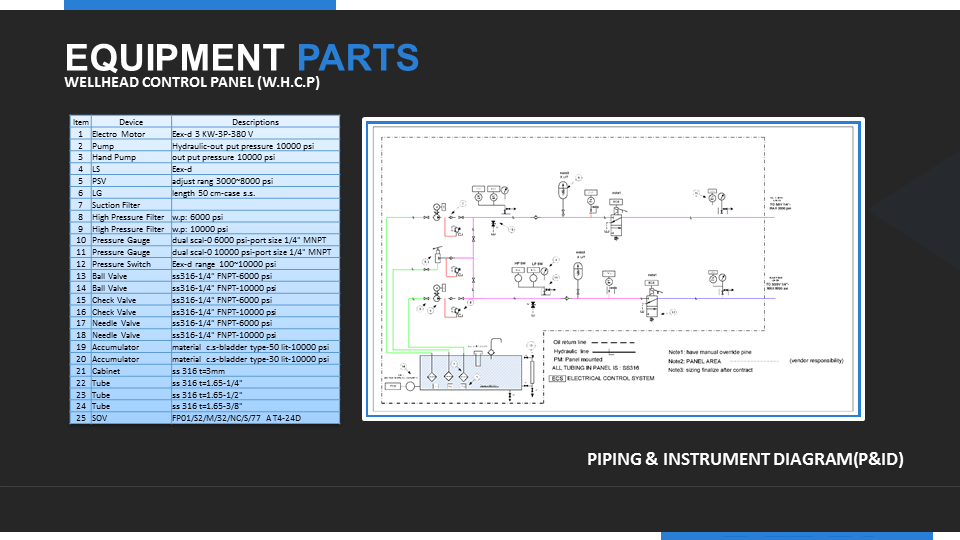

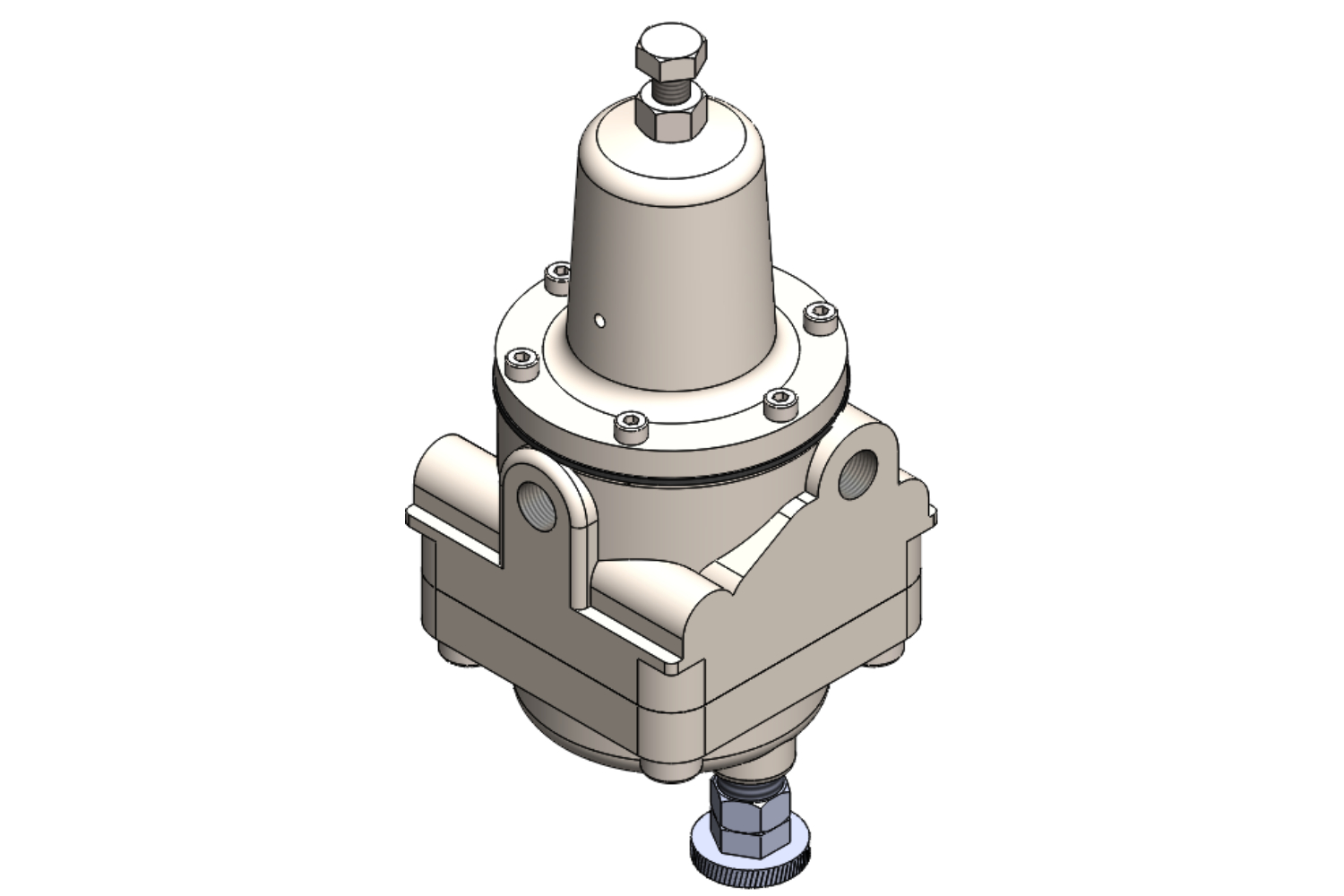

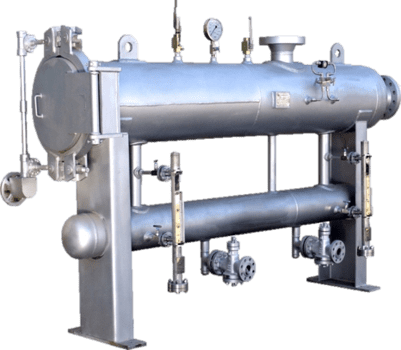

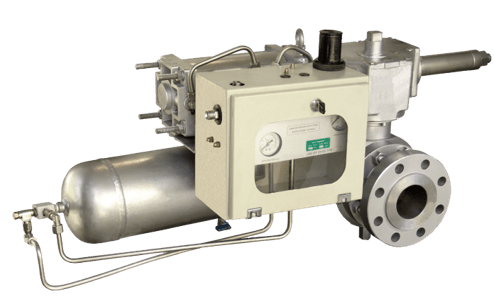

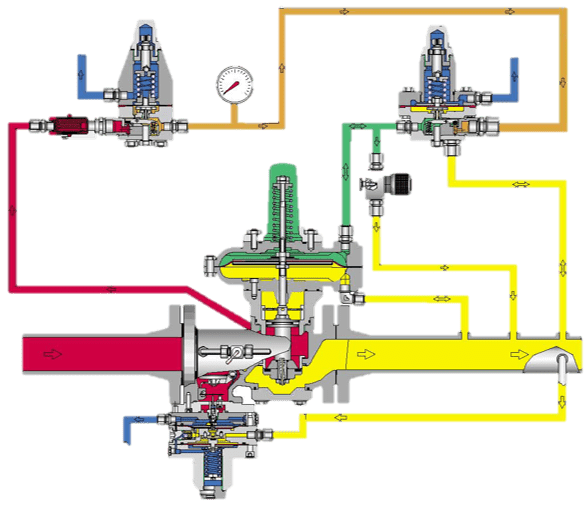

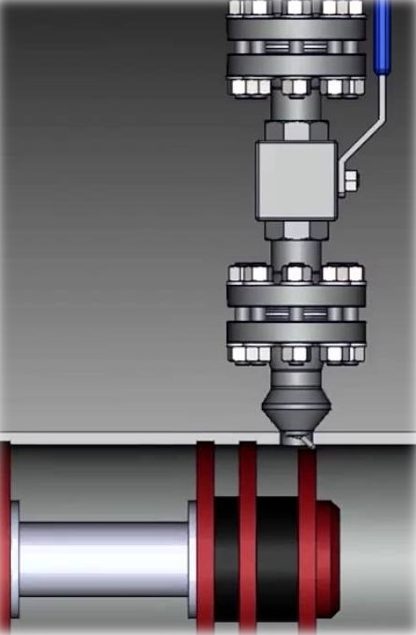

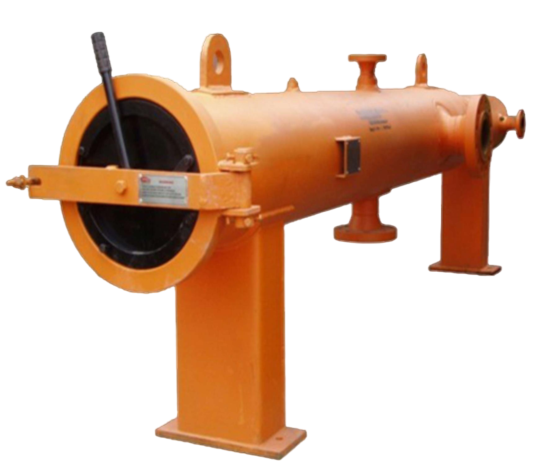

The Well Control Panel is a pneumatic/hydraulic control unit designed to safely operate for sample the three main safety valves (SSSV, SSV & SCSSV installed on a producing well. Not limited to this, it is also used to operate other actuators and valves. The unit can be sized in accordance to customer’s requirements to control the number of wellheads.

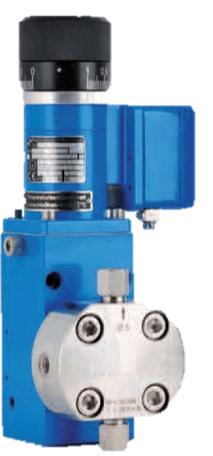

Each well has individual manual and automatic control features to allow the well to be shut down in sequence according to the pneumatic logic control or program logic control (PLC/relays). To achieve this, the Wellhead Control Panel/Rack consists of various pressure switches, sensors and solenoid valves.

PRODUCT BENEFIT

Why should you trust our WHCP?

- Avoid the dangers of life for individuals and personnel.

- Prevent oil and gas wastage due to accidents.

- Prevent damage to the environment due to oil and gas leaks.

- Improving the safety of oil wells in the event of pressure failures.

- Ready at all hours of the day.

- Ability to change all parts according to customer requirements.

- Easy maintenance of the device.

- Having a very high reaction speed when problems occur.

- Easy learning to set up and operate the device.

- Can be used in the transmission lines of various fluids outside the well.

SPECIFICATION & FEATURES

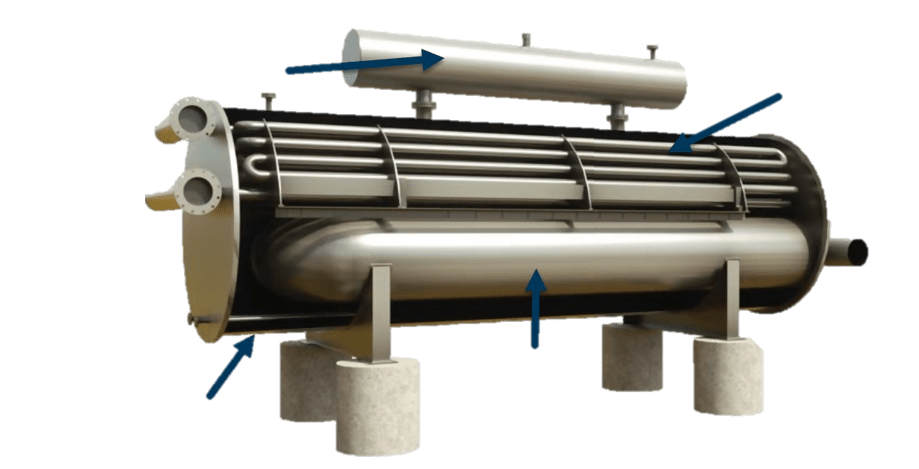

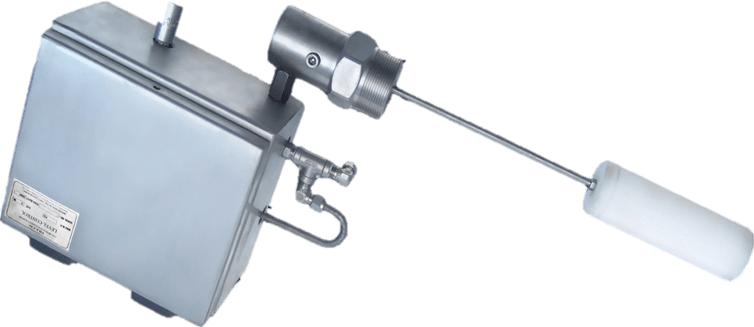

Due to lack of any pneumatic or electric power source in wellhead area, the control panel shall be stand-alone controlled via local controls and without the need of any external actuating power supply. Manual hydraulic oil pumps provided for emergency operation in the event of gas motor driven pumps failure.

Two low pressure pilots and two high pressure pilots in the panel are predicted to initiate an emergency shutdown of wellhead facilities when the pressure reduced to an adjustable minimum level or built up to an adjustable maximum level, Also a low pressure alarm will indicate low pressure of hydraulic oil, Also a low pressure alarm shall indicate low pressure of accumulator.

For detection of fire in wellhead area, 3 fusible plugs will be installed nearby Christmas tree and hydraulic panel (each of SSV and SSSV hydraulic supply lines) to initiate an emergency shutdown if necessary. The WHCP Will be equipped with its own alarm annunciation system. If the pressure on the Hydraulic power falls; then a pressure switch shall activate the related valve closed status Local flag on the panel front.

Any Internal Failure such as accumulator pressure loss; shall be alarmed by panel mounted flags. The WHCP shall latch alarms (alarms and indications shall be first in latch type) and require each alarm to be acknowledged before the alarm will clear manually.

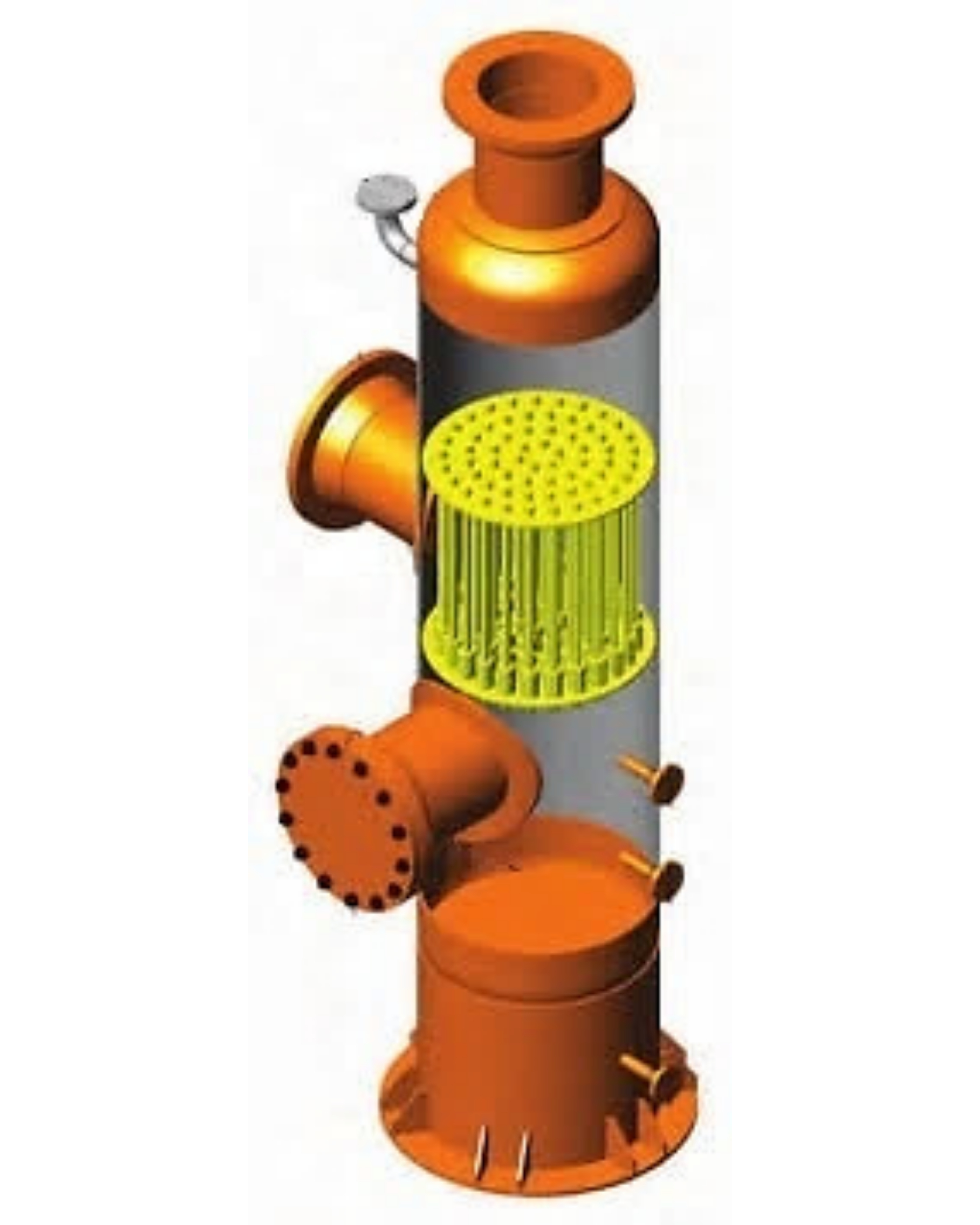

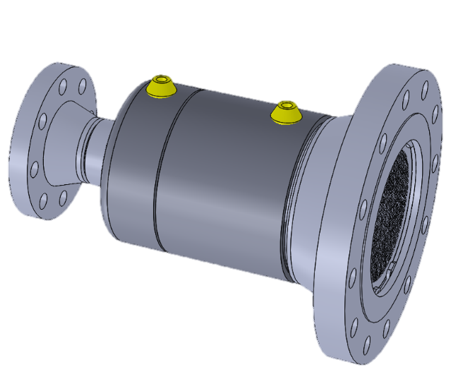

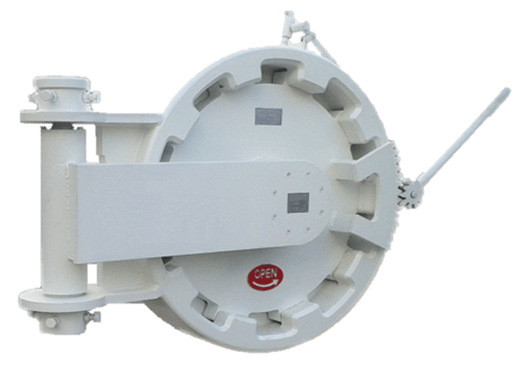

The equipment is used to actuate the subsea valves of the Christmas tree. These valves are actuated by single acting spring loaded actuator which required holding opened by Hydraulic Pressure under normal operation. This unit is designed as SSD (Safety Shutdown) system as per latest technical specifications and the actual working conditions. Apply to the effective control of SSV (Surface Safety Valve), SCSSV (Surface Controlled subsurface valve) and/or wing valve

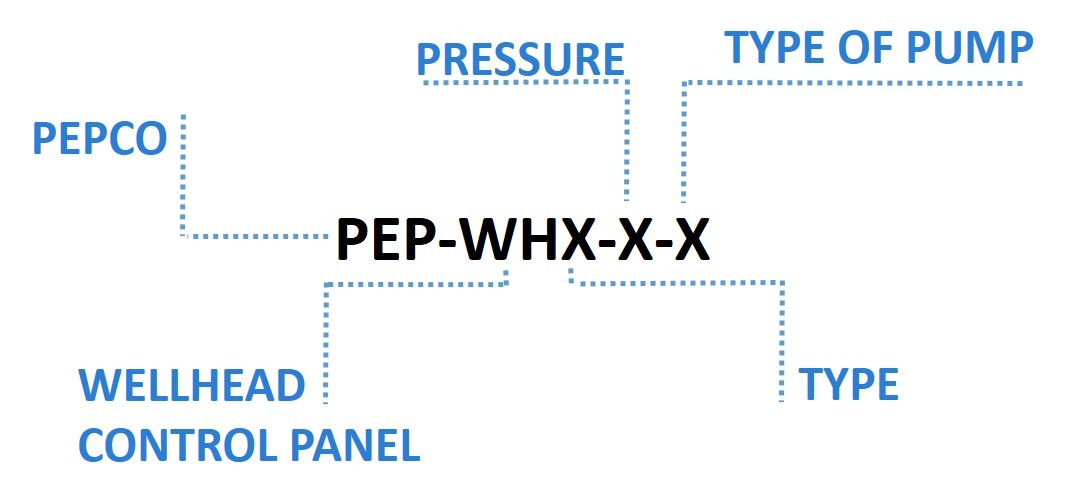

MODEL NUMBER

Contact Us

Contact Us Engineering Group

Engineering Group

Creative Strategy

Creative Strategy Download

Download